EPDM sponge rubber is one of the most widely used materials in industrial sealing and insulation applications. Manufacturers choose it because it offers excellent resistance to heat, moisture, ozone, and harsh environmental conditions. In addition, EPDM maintains flexibility in both high and low temperatures, making it ideal for demanding industrial environments.

Industries such as automotive, HVAC, construction, marine, and heavy equipment manufacturing rely on this material for long-term durability and consistent performance. For custom material solutions, you can explore our EPDM sponge rubber options designed for industrial applications.

What is EPDM Sponge Rubber?

EPDM stands for Ethylene Propylene Diene Monomer. It is a synthetic elastomer specifically engineered to withstand outdoor exposure, UV radiation, ozone, and water. Because of these characteristics, EPDM is commonly used in sealing and insulation systems.

EPDM sponge rubber is a cellular version of solid EPDM rubber. During manufacturing, air is introduced into the material, creating a sponge-like internal structure. As a result, the material becomes lightweight, compressible, and capable of forming tight seals under pressure.

This material is often referred to as:

- EPDM sponge

- EPDM rubber foam

- EPDM closed cell foam

- EPDM foam rubber

Although these terms are sometimes used interchangeably, closed-cell EPDM foam is typically preferred for industrial sealing because it blocks water absorption and improves insulation performance.

EPDM Sponge vs EPDM Closed Cell Foam

A common question is the difference between EPDM sponge and EPDM foam. The answer depends on cell structure.

Closed-cell EPDM foam contains sealed air pockets that prevent water and air from passing through the material. Therefore, it provides superior sealing and insulation properties. Open-cell sponge materials, on the other hand, allow some air flow and are used in cushioning applications.

For demanding industrial environments, manufacturers typically select EPDM sponge seal products because they offer:

- Excellent water resistance

- Airtight and dustproof sealing

- Strong compression recovery

- Long service life

- Reliable outdoor durability

This makes EPDM an ideal material for automotive weatherstripping, industrial enclosures, and HVAC insulation systems.

EPDM Temperature Rating

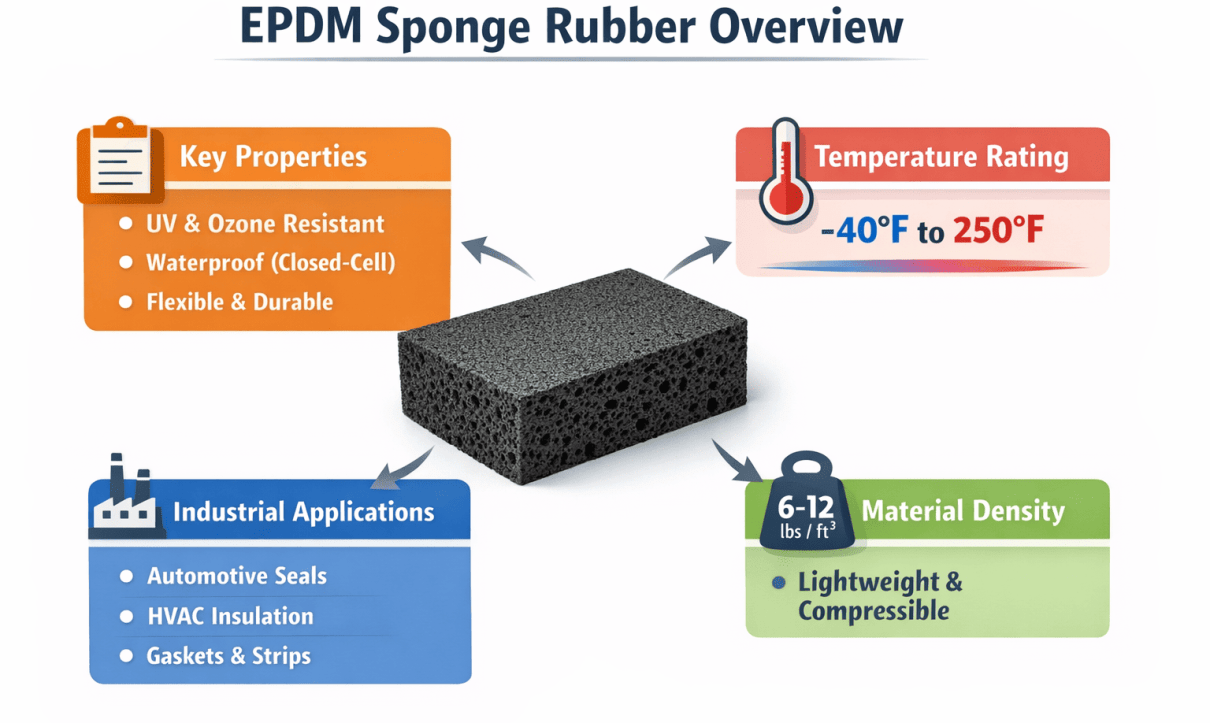

The wide EPDM temperature rating is one of the main reasons it is used across multiple industries.

Standard EPDM sponge rubber typically performs within the following temperature range:

- -40°F to 250°F

- (-40°C to 120°C)

Specially formulated compounds may tolerate even higher temperatures depending on the application.

Because of this thermal stability, EPDM rubber is commonly used in:

- Automotive engine compartments

- HVAC duct insulation

- Outdoor sealing systems

- Industrial equipment exposed to heat and vibration

Unlike many alternative materials, EPDM remains flexible even in freezing weather. This reduces cracking and failure over time.

EPDM Rubber Material Density

EPDM rubber material density directly affects its compression strength and durability. Typical EPDM sponge density ranges from 6 to 12 lbs per cubic foot, although custom densities are available for specific applications.

Lower-density sponge provides better cushioning and flexibility. Higher-density grades offer improved strength and resistance to mechanical stress.

When selecting EPDM material, consider:

- Load-bearing requirements

- Compression and recovery needs

- Environmental exposure

- Long-term durability expectations

For precision applications, manufacturers create custom-cut EPDM sponge gasket components tailored to exact dimensional requirements.

Key Properties of EPDM Sponge Rubber

EPDM sponge rubber combines flexibility with environmental resistance. Its balanced performance makes it suitable for indoor and outdoor use.

- Excellent UV resistance

- Superior ozone resistance

- Strong weather and aging resistance

- High water resistance (closed-cell structure)

- Good chemical resistance

- Low compression set

- Long service life

Because of these properties, EPDM rubber insulation and sealing systems maintain consistent performance over extended periods.

Industrial Applications of EPDM Sponge Rubber

EPDM sponge rubber serves a wide range of industrial applications that require durability and reliable sealing performance.

Automotive Industry

- Door and trunk seals

- Weatherstripping systems

- Engine compartment insulation

- Noise and vibration reduction

HVAC & Insulation

- Thermal insulation materials

- Duct sealing applications

- Air barrier systems

- Energy efficiency improvement

Industrial Equipment

- EPDM sponge tubing

- Sealing strips and protective padding

- Electrical enclosures

- Machinery housing seals

Construction & Infrastructure

- Window and door sealing

- Expansion joints

- Waterproofing systems

For strip-style sealing applications, EPDM sponge strip products provide flexible and durable sealing solutions.

Is EPDM Sponge Rubber Waterproof?

Yes. Closed-cell EPDM foam is highly resistant to water absorption. It performs well in marine environments, outdoor installations, and weather-exposed industrial equipment.

Additionally, EPDM resists UV radiation and ozone exposure. This makes it one of the most reliable materials for long-term outdoor use.

Why Choose EPDM Sponge Rubber?

Compared to many traditional rubber materials, EPDM offers superior environmental resistance and thermal stability. It delivers consistent performance in both hot and cold climates.

Whether used as sheets, tubing, strips, or custom gaskets, EPDM sponge rubber remains a dependable solution for industrial sealing and insulation needs. Partnering with an experienced rubber manufacturer in Detroit, MI ensures high-quality materials and precision manufacturing standards.

Frequently Asked Questions

What is EPDM sponge rubber used for?

EPDM sponge rubber is commonly used for sealing, insulation, vibration control, weatherstripping, and gasket manufacturing.

What is the temperature rating of EPDM rubber?

Standard EPDM rubber operates between -40°F and 250°F.

What is EPDM rubber material density?

Most EPDM sponge grades range from 6 to 12 lbs per cubic foot.

Is EPDM sponge waterproof?

Closed-cell EPDM foam resists water absorption and moisture penetration.

Which industries use EPDM sponge rubber?

Automotive, HVAC, construction, marine, and industrial manufacturing industries widely use EPDM sponge rubber.

Final Thoughts

EPDM sponge rubber continues to be one of the most dependable materials for industrial sealing and insulation. Its durability, temperature resistance, and weather performance make it ideal for demanding environments.

By selecting the right density and form, businesses can achieve long-lasting, cost-effective sealing solutions that improve performance and reliability.