If you’re searching for rubber gaskets, the right rubber gasket material, or a durable rubber gasket seal in Westland, you’re in the right place. Rubber gaskets are essential components used to prevent leaks, reduce vibration, seal out moisture, and improve product performance across industries like automotive, HVAC, manufacturing, appliances, and construction.

Rubber gaskets are sealing components placed between two surfaces to prevent leaks, air loss, dust intrusion, or vibration. They help create a secure barrier that supports performance, safety, and long-term reliability.

A properly designed rubber gasket seal helps ensure:

- A tight, consistent seal between surfaces

This reduces air and liquid leakage and improves overall performance. - Better protection from moisture, dust, and contaminants

This is especially important for machinery, enclosures, and systems that operate in challenging environments. - Improved vibration and noise reduction

Rubber gaskets absorb movement and help prevent rattling, shaking, and wear at connection points.

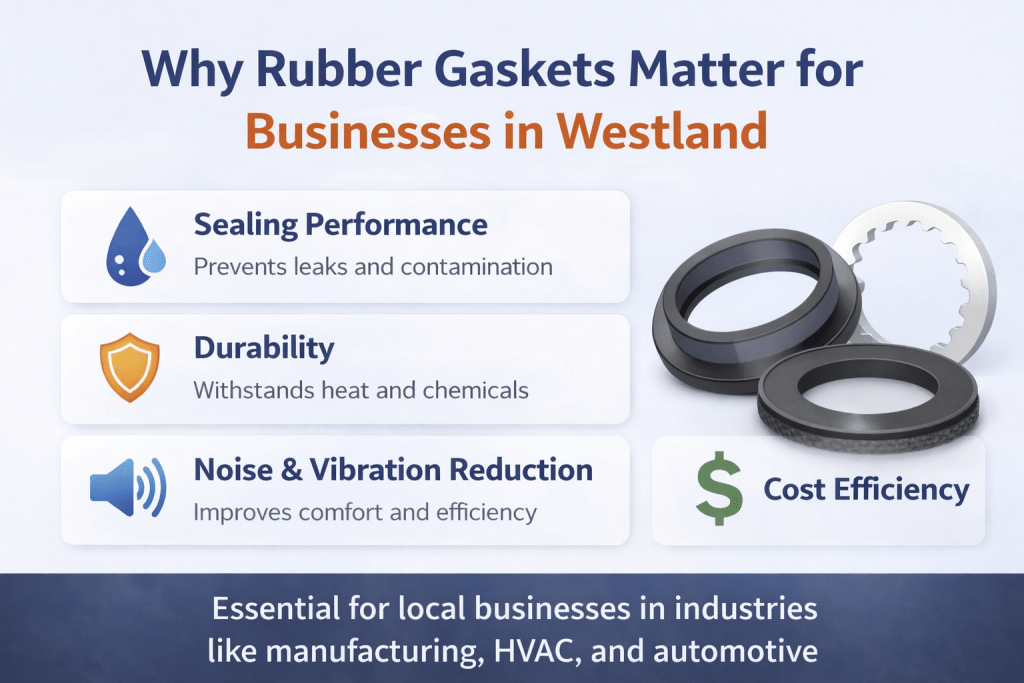

Why Rubber Gaskets Matter for Businesses in Westland

Westland businesses and facilities rely on dependable sealing solutions for equipment and assemblies that are exposed to different operational conditions.

Rubber gaskets are critical because they help address:

- Temperature changes throughout the year

The right rubber gasket material stays stable and flexible in seasonal conditions. - Vibration from machines, vehicles, and industrial equipment

Gaskets reduce stress on parts and help prevent premature failure. - Moisture exposure and environmental sealing needs

A strong gasket rubber option keeps systems protected from leaks and water intrusion. - Long-term wear caused by compression and repeated use

High-quality materials maintain sealing performance longer and reduce replacement frequency.

Rubber Gasket Material: Choosing the Right Option

Selecting the proper rubber gasket material depends on your environment, sealing requirements, compression needs, and exposure to chemicals or oils.

Below are common gasket rubber choices used across many industries.

Common Types of Gasket Rubber

EPDM Rubber Gaskets

EPDM is widely used for outdoor and weather-exposed applications.

Neoprene Rubber Gasket Material

Neoprene is a versatile rubber with balanced performance characteristics.

Silicone Rubber Gaskets

Silicone rubber is often selected for temperature stability and high-performance sealing.

Nitrile (Buna-N) Gasket Rubber

Nitrile is a preferred material when oil and fuel resistance is required.

Sponge Rubber Gaskets

Rubber gaskets made from sponge materials are compressible solutions designed to create consistent seals on uneven surfaces.

- Compresses easily to fill gaps

This makes sponge gaskets ideal for doors, panels, housings, and enclosures. - Helps reduce vibration and noise

The cushioning effect improves sealing while reducing mechanical stress. - Reliable for sealing applications needing flexibility

It provides strong surface contact even when surfaces are not perfectly flat.

Learn more about rubber gasket seal options.

Rubber Gasket Seal vs Standard Rubber Gasket: What’s the Difference?

The term rubber gasket refers to the component itself, while rubber gasket seal often refers to its sealing function and performance.

Key differences include:

- Rubber gasket

A general sealing or cushioning part used between surfaces. - Rubber gasket seal

A gasket designed specifically to create a stronger barrier against air, water, or contaminants and maintain sealing performance over time.

In practice, both terms are often used interchangeably, but seal performance depends heavily on material selection, compression, and installation.

Rubber Window Gasket: Where It’s Used and Why It Matters

A rubber window gasket is designed to seal around glass or window frames to prevent drafts, water leakage, and vibration.

A quality rubber window gasket helps with:

- Draft reduction

A better seal limits airflow leaks and improves comfort. - Water resistance

It prevents rainwater intrusion that can cause long-term damage. - Noise control

Rubber absorbs vibration and reduces rattling from wind or movement. - Improved longevity of frames and assemblies

Sealing helps protect surrounding materials from moisture and dirt buildup.

If a window gasket becomes cracked, stiff, or loose, it is often better to replace it rather than trying to restore it.

Where Rubber Gaskets Are Commonly Used

Rubber gaskets support many industries and products. Below are some of the most common uses.

How to Choose the Best Rubber Gasket Material (Westland Guide)

Before choosing your gasket rubber, consider these key factors:

Rubber Gaskets in Westland: Why Choose Excel Rubber

Excel Rubber supports customers in Westland with reliable gasket solutions designed for consistent sealing, durability, and long-term value.

If you need high-quality rubber gasket material, dependable rubber gasket seals, or sponge gasket solutions for your application, explore:

FAQ

How to shrink a rubber gasket?

Rubber gaskets typically shrink due to heat, age, or chemical exposure. In most cases, shrinking a rubber gasket back into shape is not a long-term reliable fix because the rubber structure has already changed.

A more dependable solution is replacing the gasket with the correct material and size to restore sealing performance.

How to clean washing machine rubber gasket?

To clean a washing machine rubber gasket:

- Wipe away visible debris and moisture

This removes residue that can lead to odor and buildup. - Use mild soap or a gentle cleaning solution

This helps clean the surface without damaging the rubber. - Clean inside the folds carefully

Mold and grime often collect in hidden areas. - Dry the gasket after cleaning

Drying prevents moisture from staying trapped and causing mold.

How to clean rubber gasket on front load washer?

Front load washer gaskets commonly trap moisture and soap scum, which can cause odor.

To clean it:

- Pull back the gasket folds

This exposes buildup and trapped debris. - Remove lint, hair, and residue

This prevents mold growth and keeps the seal clean. - Wipe with a soft cloth and mild cleaner

This cleans effectively without tearing or weakening the rubber. - Leave the washer door open after use

This allows airflow and reduces moisture that causes mold.

How to clean refrigerator rubber gasket?

To clean a refrigerator rubber gasket:

- Use warm water with mild soap

This removes grease and residue without harsh chemicals. - Use a soft brush for grooves

This helps reach dirt trapped in gasket ridges. - Wipe dry thoroughly

Drying improves sealing and helps prevent cracking over time.

How to clean rubber gasket in washing machine?

To clean the rubber gasket in a washing machine:

- Remove debris and standing water

This prevents odor and bacteria growth. - Clean with a non-abrasive solution

This protects the rubber and avoids surface damage. - Wipe and dry completely

This prevents moisture buildup that causes mold. - Maintain it weekly or biweekly

Regular cleaning extends gasket life and improves performance.

Need Rubber Gaskets in Westland?

If you’re looking for durable, dependable rubber gaskets in Westland with the right materials and sealing performance, Excel Rubber can help you find the right solution.