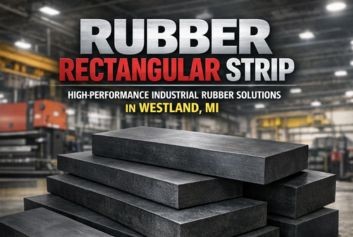

A rubber rectangular strip is one of the most versatile and widely used rubber profiles across industrial, commercial, and manufacturing environments. Because of its flat and uniform rectangular shape, this rubber product delivers consistent sealing, spacing, vibration control, insulation, and surface protection. As a result, industries depend on rubber rectangular strips for applications that require durability, flexibility, and long-term reliability.

Whether you need a cushioning solution for heavy industrial machinery or a flexible spacer for light commercial installations, rubber rectangular strips provide dependable performance. Moreover, they adapt easily to different working conditions, installation methods, and material requirements.

Manufactured with precision and engineered for demanding applications, rubber rectangular strips supplied from 38195 Executive Drive, Westland, MI 48185, USA meet strict industrial standards. These products support a wide range of industries while maintaining dimensional accuracy, material consistency, and extended service life.

What Is a Rubber Rectangular Strip?

A rubber rectangular strip is a solid rubber profile with consistent width and thickness throughout its length. Unlike molded gaskets or complex extrusions, rectangular strips focus on simplicity, strength, and adaptability. Because of this straightforward design, they integrate easily into numerous applications without specialized tooling.

In addition, rubber rectangular strips allow easy cutting, trimming, bonding, or fastening. Therefore, they remain a cost-effective solution for both custom projects and large-scale production needs.

Common uses include sealing joints, acting as spacers, reducing vibration, protecting surfaces, and preventing metal-to-metal contact. Due to their adaptable nature, these strips work well in both temporary and permanent installations.

Key Benefits of Rubber Rectangular Strips

Rubber rectangular strips provide multiple functional advantages that support performance, safety, and durability.

Long-Lasting Durability

High-quality rubber compounds resist tearing, abrasion, compression set, and cracking. Consequently, rectangular strips continue to perform reliably even in demanding industrial environments.

Reliable Sealing Performance

Because of their uniform cross-section, these strips compress evenly. As a result, they create effective seals against dust, moisture, air, and debris.

Vibration and Noise Reduction

Rubber naturally absorbs vibration and sound. Therefore, rectangular strips help reduce operational noise and protect equipment from vibration-related wear.

Environmental Resistance

Depending on the selected compound, rubber rectangular strips resist UV exposure, ozone, moisture, oils, chemicals, and temperature changes. This flexibility allows use in both indoor and outdoor environments.

Simple Customization and Installation

Rectangular rubber strips are available in various widths, thicknesses, hardness levels, and materials. Additionally, installers can cut and shape them easily, which reduces installation time and labor costs.

Common Applications of Rubber Rectangular Strips

Because of their versatility, rubber rectangular strips serve many industries and applications.

Industrial Machinery and Manufacturing Equipment

Manufacturers commonly use rectangular rubber strips as spacers, pads, and vibration dampeners. These strips protect machinery components while reducing wear and operational stress.

Automotive and Transportation Systems

In automotive and transportation environments, rectangular strips help seal panels, cushion assemblies, and reduce vibration. As a result, they improve ride comfort, noise control, and component longevity.

Construction and Infrastructure Projects

Construction professionals rely on rubber rectangular strips for expansion joints, leveling pads, and protective barriers. These applications help distribute loads evenly and prevent structural damage.

Electrical and Electronics Applications

Rubber rectangular strips provide insulation and shock absorption in electrical enclosures, control panels, and electronic housings. Because rubber is non-conductive, it enhances system safety.

HVAC and Mechanical Systems

In HVAC units and mechanical assemblies, rectangular rubber strips reduce vibration, seal gaps, and protect components from friction and wear.

Rubber Materials Used in Rectangular Strips

The performance of a rubber rectangular strip depends heavily on the rubber compound used. Selecting the right material ensures optimal results.

EPDM Rubber

EPDM rubber performs exceptionally well in outdoor and weather-exposed applications. It resists UV rays, ozone, moisture, and temperature extremes.

Neoprene Rubber

Neoprene offers balanced resistance to weather, oils, chemicals, and abrasion. Therefore, it works well in industrial and automotive environments.

Nitrile (NBR) Rubber

Nitrile rubber resists oils, fuels, and greases effectively. As a result, it suits manufacturing, mechanical, and automotive applications.

Natural Rubber

Natural rubber provides excellent elasticity, tensile strength, and resilience. It works best in vibration isolation and shock absorption applications.

Silicone Rubber

Silicone rubber maintains flexibility at high and low temperatures. Consequently, it supports applications requiring thermal stability.

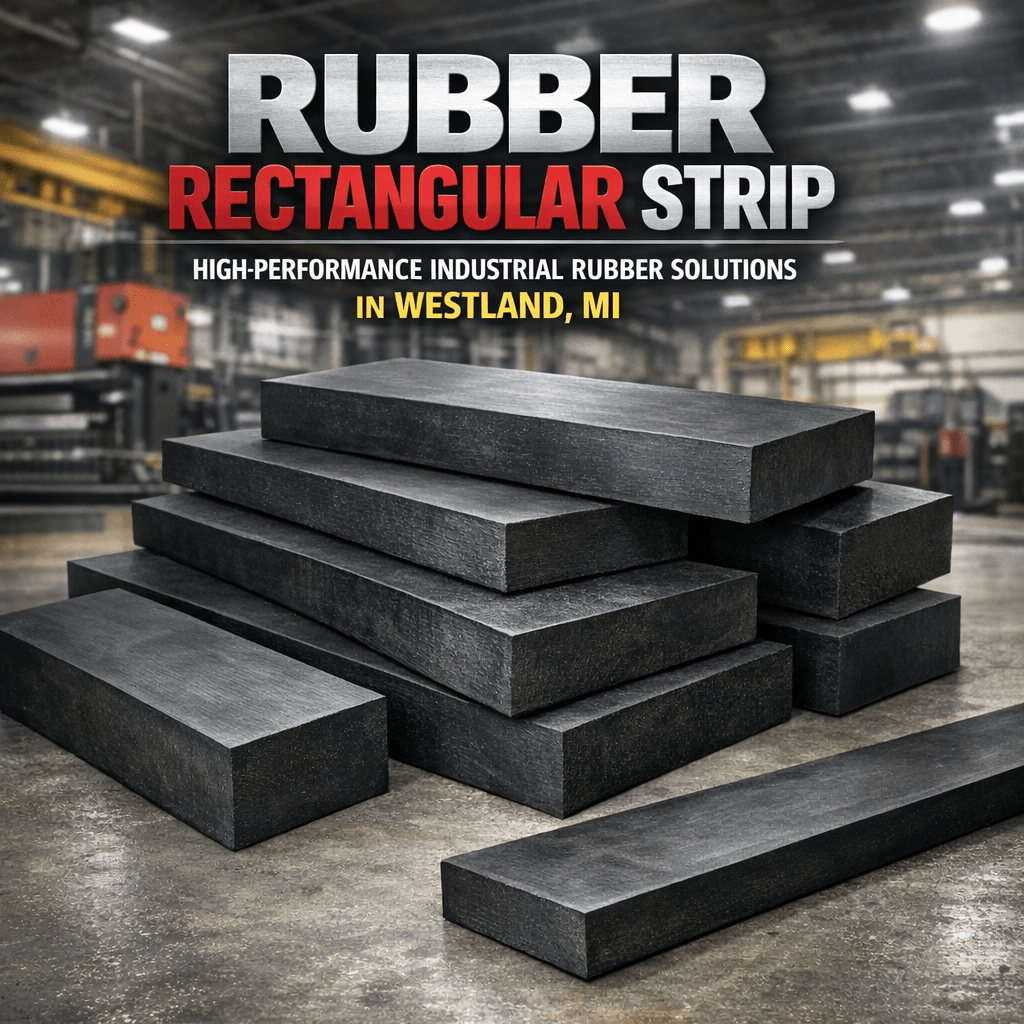

Custom Rubber Rectangular Strip Manufacturing

Custom manufacturing allows rubber rectangular strips to meet precise application requirements. Instead of adapting your system to standard products, custom strips fit seamlessly into your design.

Customization options include width, thickness, length, hardness, material type, color, and surface finish. By choosing custom dimensions, businesses improve performance while reducing installation adjustments and material waste.

Custom rubber rectangular strips also ensure consistent compression, proper sealing, and reliable long-term performance.

Advantages of Local Manufacturing in Westland, MI

Sourcing rubber rectangular strips from Westland, Michigan offers multiple advantages.

Local manufacturing ensures faster turnaround times, better communication, and consistent quality control. Additionally, proximity to manufacturing facilities allows quick response to design changes, material adjustments, or urgent production needs.

Operating from 38195 Executive Drive, Westland, MI 48185, manufacturers maintain strict quality standards while supporting businesses across Michigan and the USA.

Load-Bearing and Structural Support Applications

Rubber rectangular strips can support compressive loads when manufactured with appropriate hardness and material selection. In these cases, they distribute weight evenly and prevent stress concentration.

Common load-bearing uses include equipment leveling pads, machinery bases, conveyor supports, and structural separation layers. These applications help protect both equipment and surrounding structures.

Impact Protection and Workplace Safety

Safety remains a priority in industrial and commercial environments. Rubber rectangular strips often function as bumpers, guards, or protective barriers.

When installed correctly, these strips absorb impact energy during collisions or sudden movements. As a result, they reduce equipment damage and minimize injury risk.

Warehouses, loading docks, and manufacturing floors benefit significantly from impact-resistant rubber components.

Electrical Insulation and Non-Conductive Benefits

Rubber’s natural insulating properties make rectangular strips ideal for electrical systems. They prevent accidental contact with live components while also absorbing vibration.

These strips commonly appear in electrical panels, switchgear, battery compartments, and cable management systems.

Performance in Extreme Temperatures

Rubber rectangular strips can operate across wide temperature ranges when the correct compound is selected. High-temperature environments include engine compartments, industrial ovens, and HVAC systems. Meanwhile, low-temperature environments include cold storage facilities and outdoor installations.

Choosing the appropriate rubber material ensures flexibility, sealing integrity, and durability despite temperature fluctuations.

Environmental Resistance and Longevity

Environmental exposure often leads to material degradation. However, rubber rectangular strips resist many environmental stress factors such as moisture, UV radiation, ozone, air pollutants, and chemicals.

Because of this resistance, they maintain performance over extended periods with minimal maintenance.

Fabrication Flexibility and Precision Cutting

Rubber rectangular strips offer excellent fabrication flexibility. Manufacturers can supply them in continuous lengths or precision-cut pieces.

Available fabrication options include straight cuts, mitered ends, adhesive-backed strips, and laminated assemblies. These options reduce installation time and improve overall efficiency.

Cost Efficiency and Long-Term Value

Rubber rectangular strips deliver strong long-term value. Their durability reduces replacement frequency, while their simple design keeps production costs manageable.

Compared to metal or rigid plastic alternatives, rubber strips provide superior flexibility, vibration absorption, and environmental resistance at a lower overall cost.

Compatibility With Installation Methods

Rubber rectangular strips work with various installation methods, including industrial adhesives, pressure-sensitive tapes, mechanical fasteners, and compression fitting.

This compatibility allows easy integration into new systems or retrofitting existing equipment.

OEM and Replacement Applications

Original equipment manufacturers rely on rubber rectangular strips for consistent quality and predictable performance. Meanwhile, maintenance teams use them for quick replacements and system upgrades.

Because rectangular strips cut easily to size, they simplify repairs without requiring full component replacement.

Noise Reduction and Comfort Improvement

Noise control remains essential in industrial and commercial spaces. Rubber rectangular strips reduce noise by absorbing vibration and preventing rigid contact between components.

They support quieter operation in machinery housings, HVAC systems, generator enclosures, and building structures.

Compliance With Industry Standards

High-quality rubber rectangular strips meet industry standards for material performance, safety, and dimensional accuracy. As a result, they suit regulated industries such as automotive, electrical, construction, and manufacturing.

Scalability for Any Project Size

Whether for small custom projects or large-scale production, rubber rectangular strips scale efficiently. Consistent extrusion processes maintain quality regardless of order size.

Frequently Asked Questions

What is a rubber rectangular strip used for?

Rubber rectangular strips are used for sealing, spacing, vibration isolation, insulation, impact protection, and noise reduction.

Can rubber rectangular strips be customized?

Yes, they can be customized by size, material, hardness, color, and length to match specific applications.

Which rubber material works best outdoors?

EPDM rubber works best for outdoor use because it resists UV rays, ozone, moisture, and temperature changes.

Are rubber rectangular strips oil-resistant?

Nitrile and neoprene rubber strips provide excellent resistance to oils, fuels, and greases.

How long do rubber rectangular strips last?

With proper material selection and installation, rubber rectangular strips can last many years in normal operating conditions.

Are rubber rectangular strips easy to install?

Yes, they install easily using adhesives, fasteners, or compression fitting and require minimal tools.

Final Thoughts

A rubber rectangular strip may appear simple, yet it delivers powerful performance across countless applications. From sealing and spacing to vibration control, insulation, and safety protection, these rubber profiles play a vital role in modern industry.

Manufactured with precision in Westland, Michigan, rubber rectangular strips offer durability, adaptability, and long-term value. When engineered with the right material and dimensions, they enhance efficiency, protect equipment, and support reliable operation for years to come.

Extended Industry Use Cases for Rubber Rectangular Strips

Beyond standard industrial applications, rubber rectangular strips continue to gain importance in specialized industries that require precision, resilience, and adaptability. Because these strips maintain consistent dimensions and predictable compression behavior, engineers often specify them for systems that demand repeatable performance.

In packaging and material handling systems, rubber rectangular strips guide products, cushion impacts, and reduce friction. Similarly, in automated production lines, they help stabilize moving parts while minimizing vibration transfer. As automation increases across industries, the demand for reliable rubber components like rectangular strips continues to grow.

Role in Equipment Longevity and Preventive Maintenance

Rubber rectangular strips play a vital role in extending equipment life. When placed between rigid components, they reduce direct contact and absorb mechanical stress. Over time, this protection prevents surface wear, loosening of fasteners, and structural fatigue.

Maintenance teams frequently use rectangular rubber strips as part of preventive maintenance programs. By replacing worn strips at scheduled intervals, facilities can avoid costly breakdowns and unplanned downtime. This proactive approach improves operational efficiency and reduces long-term maintenance expenses.

Performance Under Repeated Compression Cycles

Many applications subject rubber rectangular strips to repeated compression and relaxation cycles. In such environments, material quality becomes critical. High-grade rubber compounds maintain elasticity and recover their original shape even after extended use.

This ability to withstand repeated stress makes rectangular strips ideal for dynamic applications such as machinery mounts, moving assemblies, and vibration isolation systems. Over time, consistent performance ensures stable operation and reliable system behavior.

Contribution to Workplace Ergonomics

Rubber rectangular strips also contribute to improved workplace ergonomics. When used as anti-fatigue supports, padding elements, or surface protectors, they help reduce physical strain on workers.

For example, rubber strips placed on workstations or assembly benches absorb shock and reduce vibration transmitted to hands and arms. Consequently, workers experience improved comfort, reduced fatigue, and enhanced productivity.

Application in Water and Moisture-Control Environments

Moisture exposure presents a challenge in many industries. Rubber rectangular strips offer effective solutions due to their water-resistant properties. When installed as seals or barriers, they prevent water infiltration and protect sensitive components.

Common moisture-control applications include water treatment facilities, marine environments, outdoor equipment enclosures, and plumbing systems. Selecting the correct rubber compound ensures consistent sealing performance even in wet conditions.

Compatibility With Metal, Plastic, and Composite Materials

Rubber rectangular strips integrate easily with various materials, including metals, plastics, and composites. Their flexibility allows them to conform to surface irregularities while maintaining consistent contact.

This compatibility proves valuable in mixed-material assemblies where different components expand or contract at varying rates. Rubber strips accommodate this movement, thereby preventing stress buildup and component failure.

Precision Engineering and Dimensional Stability

Dimensional stability is critical in precision engineering. Rubber rectangular strips manufactured with tight tolerances maintain consistent thickness and width throughout their length. This consistency ensures predictable compression and reliable performance.

In applications such as tooling, fixtures, and calibration equipment, even minor dimensional variations can affect outcomes. Rectangular rubber strips help maintain accuracy and repeatability in these sensitive environments.

Role in Energy Absorption and Shock Mitigation

Rubber rectangular strips excel at absorbing energy during sudden impacts or load changes. This characteristic protects equipment and surrounding structures from damage caused by shock forces.

In industrial settings, shock mitigation improves safety and reduces repair costs. Rubber strips installed in strategic locations absorb impact energy and prevent it from transferring to vulnerable components.

Use in Agricultural and Outdoor Equipment

Agricultural and outdoor equipment often operate in harsh conditions involving dust, moisture, temperature changes, and mechanical stress. Rubber rectangular strips withstand these challenges while maintaining flexibility and sealing performance.

They are commonly used in farming machinery, irrigation systems, outdoor enclosures, and equipment housings. Their resistance to environmental exposure ensures reliable operation across seasons.

Custom Hardness Selection for Specific Applications

Hardness, measured in durometer, directly affects rubber strip performance. Softer compounds offer greater flexibility and cushioning, while harder compounds provide structural support and load-bearing capability.

By selecting the appropriate hardness, engineers can fine-tune rectangular rubber strips to match application requirements. This customization improves performance and extends service life.

Integration Into Lean Manufacturing Systems

Lean manufacturing focuses on efficiency, waste reduction, and process optimization. Rubber rectangular strips support these goals by reducing equipment wear, minimizing downtime, and simplifying installation.

Because rectangular strips cut easily to size and install quickly, they reduce material waste and labor time. As a result, they align well with lean production principles.

Thermal and Acoustic Insulation Benefits

In addition to vibration control, rubber rectangular strips provide thermal and acoustic insulation. When installed as barriers or separators, they limit heat transfer and reduce noise transmission.

These properties benefit industrial facilities, commercial buildings, and mechanical systems where temperature control and noise reduction are priorities.

Sustainability and Responsible Material Use

Modern rubber manufacturing increasingly emphasizes sustainability. Durable rubber rectangular strips reduce replacement frequency, which lowers material consumption over time.

Furthermore, selecting long-lasting rubber components supports responsible resource use and reduces operational waste. Many facilities consider these factors when choosing rubber products for long-term applications.

Support for Prototyping and Product Development

Rubber rectangular strips also play an important role during prototyping and product development. Engineers often use them to test spacing, sealing, or vibration control before finalizing designs.

Because rectangular strips are easy to modify and replace, they allow quick adjustments during testing phases. This flexibility speeds up development cycles and improves design outcomes.

Importance in Emergency and Safety Systems

In emergency systems, reliability is critical. Rubber rectangular strips help ensure consistent sealing, cushioning, and protection in safety-related equipment.

Applications include protective enclosures, emergency shutoff systems, and safety barriers. The dependable performance of rubber strips supports overall system reliability.

Long-Term Reliability in High-Usage Environments

High-usage environments place continuous stress on components. Rubber rectangular strips designed for durability maintain performance even under constant use.

Factories, distribution centers, and processing plants rely on these strips for dependable operation. Their ability to perform consistently under stress supports uninterrupted production.

Future Outlook for Rubber Rectangular Strips

As industries continue to evolve, rubber rectangular strips remain essential components. Advances in material science continue to improve durability, chemical resistance, and environmental performance.

With growing demand for efficient, reliable, and adaptable solutions, rectangular rubber strips will continue to support industrial growth and innovation.

Final Extended Conclusion

Rubber rectangular strips deliver far more value than their simple design suggests. From vibration control and sealing to shock absorption, insulation, and equipment protection, these rubber profiles support critical functions across industries.

Their adaptability, durability, and customization options make them an excellent choice for both standard and specialized applications. When sourced and engineered correctly, rubber rectangular strips enhance performance, improve safety, and reduce long-term operational costs.

By integrating high-quality rubber rectangular strips into your systems, you ensure reliable operation, improved efficiency, and long-term value for years to come.