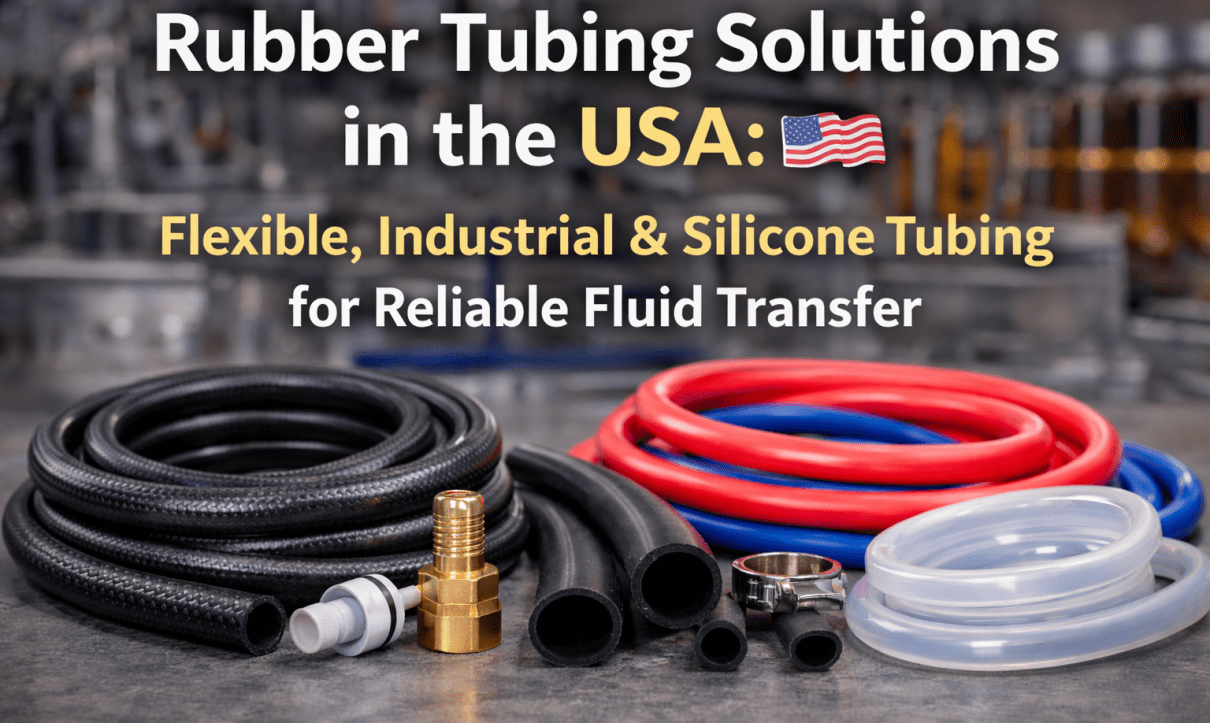

Rubber tubing is a vital component across multiple industries in the United States. From manufacturing floors and automotive systems to medical equipment and food-grade processing lines, rubber tubing enables safe, efficient, and controlled movement of fluids, gases, and air. Choosing the right rubber tubing directly impacts system performance, safety compliance, and long-term operating costs.

At Excel Rubber, we manufacture and supply high-quality rubber tubing, flexible rubber tubing, industrial rubber tubing, silicone rubber tubing, and rubber tubing for fluid transfer designed to meet the demanding requirements of U.S. industries. This in-depth guide explains types of rubber tubing, applications, materials, selection factors, and why quality tubing matters.

What Is Rubber Tubing and Why It’s Widely Used in the USA

Rubber tubing is a hollow cylindrical product designed to transport liquids, gases, chemicals, and air between components or systems. Unlike rigid piping, rubber tubing provides flexibility, vibration absorption, and resistance to environmental stress.

In the USA, rubber tubing is commonly used because it offers:

- Flexibility for tight installations

- Resistance to pressure, temperature, and chemicals

- Reduced stress on connectors and fittings

- Cost-effective installation and maintenance

Industries across the country rely on rubber tubing for reliability, efficiency, and compliance with safety standards.

Flexible Rubber Tubing: Engineered for Movement and Adaptability

Flexible rubber tubing is designed to bend, stretch, and flex without collapsing or cracking. This makes it ideal for systems exposed to motion, vibration, or frequent adjustments.

Benefits of Flexible Rubber Tubing

- Easy routing around corners and obstacles

- Reduced risk of leaks at joints

- Absorbs vibration from machinery

- Minimizes mechanical stress on equipment

Common Applications in the USA

Flexible rubber tubing is widely used in:

- Automotive coolant and fuel systems

- Pneumatic air lines

- HVAC drainage systems

- Industrial machinery with moving components

By allowing controlled movement, flexible rubber tubing improves system durability and reduces maintenance downtime.

Industrial Rubber Tubing for Heavy-Duty Applications

Industrial rubber tubing is manufactured for harsh environments where standard tubing may fail. It is designed to handle higher pressures, abrasive materials, chemical exposure, and extreme temperatures.

Why Industrial-Grade Tubing Matters

In industrial operations, tubing failure can lead to production loss, safety hazards, and regulatory violations. High-quality industrial rubber tubing ensures consistent performance under demanding conditions.

Typical Industrial Uses

- Chemical processing plants

- Oil and gas facilities

- Manufacturing fluid systems

- Construction and heavy equipment

- Mining and material handling

Industrial rubber tubing is often reinforced and formulated for long service life in aggressive environments.

Silicone Rubber Tubing: High-Performance and Food-Grade Solution

Silicone rubber tubing is a premium option known for its purity, temperature stability, and flexibility. It performs exceptionally well in both extreme heat and cold.

Key Properties of Silicone Rubber Tubing

- Excellent temperature resistance

- Non-toxic, odorless, and tasteless

- UV and ozone resistant

- Smooth inner surface for clean fluid flow

Applications in the USA

Silicone rubber tubing is commonly used in:

- Food and beverage processing

- Pharmaceutical manufacturing

- Medical devices and laboratories

- High-temperature fluid transfer systems

Because silicone rubber tubing meets strict hygiene and safety standards, it is trusted across regulated U.S. industries.

Rubber Tubing for Fluid Transfer: Safe and Efficient Flow

Rubber tubing for fluid transfer is engineered to transport liquids and gases without leakage, contamination, or degradation. Selecting the correct tubing is essential for maintaining product integrity and system efficiency.

Fluids Commonly Transferred

- Water and coolants

- Oils and fuels

- Chemicals and solvents

- Compressed air and gases

- Food-grade liquids

What Defines High-Quality Fluid Transfer Tubing

- Chemical compatibility with transferred media

- Resistance to pressure and temperature changes

- Smooth internal bore for consistent flow

- Durable construction for long-term use

Using the right rubber tubing for fluid transfer reduces the risk of system failure and operational downtime.

Materials Used in Rubber Tubing Manufacturing

Rubber tubing is manufactured using different elastomers, each offering unique performance characteristics. Choosing the correct material ensures optimal durability and safety.

Common Rubber Tubing Materials

- Natural Rubber: Excellent elasticity and abrasion resistance

- EPDM Rubber: Superior resistance to heat, weather, and ozone

- Neoprene: Balanced resistance to oil, chemicals, and weather

- Silicone Rubber: High purity and temperature stability

- Nitrile (NBR): Strong resistance to oils and fuels

Material selection depends on fluid type, temperature range, pressure, and environmental exposure.

How to Choose the Right Rubber Tubing for Your Application

Selecting the correct rubber tubing is critical for performance, safety, and compliance.

Key Selection Factors

- Type of fluid or gas being transferred

- Operating temperature and pressure

- Required flexibility and bend radius

- Exposure to chemicals, UV, or ozone

- Compliance with U.S. industry standards

Working with an experienced rubber manufacturer helps ensure the tubing meets both technical and regulatory requirements.

Why Quality Rubber Tubing Matters

Low-quality tubing may appear cost-effective initially, but it often leads to leaks, failures, and frequent replacements. Investing in high-quality rubber tubing improves system reliability and reduces long-term costs.

Benefits of High-Quality Rubber Tubing

- Longer service life

- Improved safety and compliance

- Reduced maintenance and downtime

- Consistent performance under stress

For U.S. businesses, quality tubing is an essential investment in operational efficiency.

Rubber Tubing Applications Across U.S. Industries

Rubber tubing supports critical systems across a wide range of American industries.

Industries That Depend on Rubber Tubing

- Manufacturing and fabrication

- Automotive and transportation

- HVAC and refrigeration

- Medical and healthcare

- Food and beverage processing

- Agriculture and irrigation

Each industry relies on specific tubing properties to meet its unique operational demands.

Maintenance Tips to Extend Rubber Tubing Life

Proper care and maintenance significantly extend the lifespan of rubber tubing.

Best Practices

- Conduct routine inspections

- Avoid exceeding rated pressure or temperature

- Prevent kinks and sharp bends

- Replace tubing at recommended intervals

- Store unused tubing in cool, dry conditions

Preventive maintenance reduces unexpected failures and improves system reliability.

Why Choose Excel Rubber for Rubber Tubing in the USA

Excel Rubber is a trusted supplier of rubber tubing, flexible rubber tubing, industrial rubber tubing, silicone rubber tubing, and rubber tubing for fluid transfer across the United States.

What Sets Excel Rubber Apart

- High-quality materials and precise manufacturing

- Consistent performance across applications

- Custom and standard tubing solutions

- Industry knowledge and responsive support

- Products built for real-world conditions

Our commitment to quality ensures dependable performance in every application.

Custom Rubber Tubing Solutions for Specialized USA Applications

Not all applications can be served by off-the-shelf tubing. Many U.S. industries require custom rubber tubing solutions designed for specific dimensions, material properties, or operating conditions. Customization ensures optimal performance, safety, and longevity.

When Custom Rubber Tubing Is Required

- Non-standard inner or outer diameters

- Unique wall thickness requirements

- Specialized chemical or temperature exposure

- Tight bend radius or extreme flexibility needs

- Compliance with FDA, ASTM, or industrial standards

Custom rubber tubing allows engineers and facility managers to eliminate compromises that often lead to system inefficiencies or premature failures.

Rubber Tubing Standards and Compliance in the USA

In the United States, rubber tubing used in industrial, medical, and food-grade applications must meet strict standards. Compliance is essential not only for safety but also for regulatory approval and liability protection.

Common U.S. Standards for Rubber Tubing

- FDA compliance for food and pharmaceutical use

- ASTM specifications for material performance

- SAE standards for automotive applications

- USP Class VI for medical-grade tubing

Using compliant rubber tubing ensures consistent performance, protects end users, and supports operational credibility in regulated industries.

Rubber Tubing vs Plastic Tubing: Which Is Better?

Many buyers compare rubber tubing with plastic alternatives. While plastic tubing may be suitable for some light-duty applications, rubber tubing offers significant advantages in demanding environments.

Advantages of Rubber Tubing

- Superior flexibility and elasticity

- Better resistance to vibration and mechanical stress

- Wider temperature tolerance

- Stronger chemical resistance depending on compound

- Longer service life in dynamic systems

Rubber tubing is often preferred in U.S. industrial settings where reliability and durability outweigh minimal upfront cost savings.

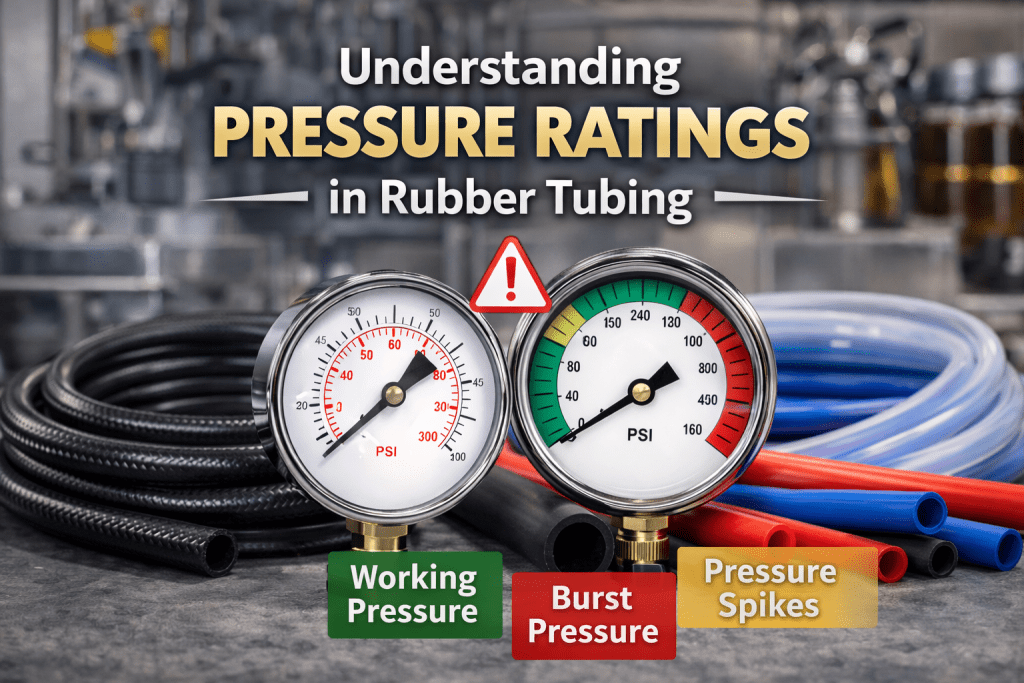

Understanding Pressure Ratings in Rubber Tubing

Pressure rating is one of the most critical factors when selecting rubber tubing for fluid transfer. Using tubing that cannot handle system pressure can result in leaks, bursts, or system shutdowns.

Types of Pressure Considerations

- Working pressure (continuous operation)

- Burst pressure (maximum failure threshold)

- Pressure surges and spikes

- Vacuum or negative pressure resistance

Industrial rubber tubing is often reinforced or engineered to maintain structural integrity under fluctuating pressure conditions common in manufacturing environments.

Temperature Resistance: Why Material Choice Matters

Temperature extremes are a leading cause of tubing degradation. Selecting the right rubber compound ensures tubing maintains flexibility and strength across its operating range.

Temperature Performance by Material

- Natural rubber: Moderate temperature tolerance

- EPDM rubber: Excellent heat and weather resistance

- Silicone rubber tubing: Outstanding high and low temperature stability

- Nitrile rubber: Suitable for oil-based fluids with moderate heat

For high-temperature or cold-weather environments in the USA, silicone rubber tubing is often the preferred solution.

Chemical Compatibility and Rubber Tubing Performance

Chemical exposure can quickly degrade improper tubing material. Rubber tubing must be compatible with the fluids it transports to avoid swelling, cracking, or contamination.

Common Chemical Compatibility Needs

- Oils and fuels

- Acids and alkalis

- Solvents and cleaning agents

- Coolants and lubricants

Industrial rubber tubing designed for chemical resistance helps protect both equipment and personnel.

Environmental Resistance: Outdoor and Harsh Conditions

Rubber tubing used outdoors or in harsh environments must resist environmental degradation.

Environmental Challenges Rubber Tubing Can Handle

- UV radiation

- Ozone exposure

- Moisture and humidity

- Temperature fluctuations

EPDM and silicone rubber tubing are particularly effective in outdoor and weather-exposed applications across the United States.

Rubber Tubing in Automotive and Transportation Systems

Automotive and transportation systems rely heavily on flexible and durable rubber tubing.

Typical Uses

- Fuel delivery systems

- Coolant circulation

- Emission control systems

- Vacuum and air lines

Flexible rubber tubing reduces vibration-related failures while ensuring reliable fluid transfer under varying driving conditions.

Medical and Laboratory Use of Silicone Rubber Tubing

Silicone rubber tubing is widely used in U.S. medical and laboratory environments due to its cleanliness and stability.

Medical Applications

- Peristaltic pumps

- Fluid delivery systems

- Laboratory testing equipment

- Diagnostic devices

Its non-reactive nature ensures safe interaction with sensitive fluids and biological materials.

Sustainability and Longevity of Rubber Tubing

High-quality rubber tubing contributes to sustainability by reducing waste and replacement frequency.

Sustainability Benefits

- Longer service life

- Reduced material waste

- Lower maintenance resource usage

- Improved energy efficiency through leak prevention

Choosing durable rubber tubing aligns with modern sustainability goals across U.S. industries.

Signs You Need to Replace Rubber Tubing

Even the best tubing has a service life. Knowing when to replace it prevents unexpected failures.

Warning Signs

- Cracks or surface hardening

- Swelling or softening

- Discoloration or odor

- Reduced flexibility

- Frequent leaks or pressure loss

Regular inspection ensures systems remain safe and efficient.

Expanded FAQs: Rubber Tubing (Trending Search-Based)

How long does rubber tubing last?

Lifespan depends on material, application, and maintenance. High-quality rubber tubing can last several years under proper conditions.

Can rubber tubing be used outdoors?

Yes. Materials like EPDM and silicone rubber tubing are well-suited for outdoor and weather-exposed applications.

Is silicone rubber tubing better than standard rubber tubing?

Silicone rubber tubing offers superior temperature resistance and purity but may not be necessary for all applications.

What industries use industrial rubber tubing the most?

Manufacturing, chemical processing, automotive, HVAC, agriculture, and construction industries are major users.

Can rubber tubing be cut to length?

Yes. Rubber tubing can be cut and customized to specific length requirements for installation.

Is rubber tubing suitable for vacuum applications?

Certain rubber tubing formulations are designed to withstand vacuum pressure without collapsing.

Final Conclusion: Choosing the Right Rubber Tubing in the USA

Selecting the correct rubber tubing is a critical decision that affects system safety, performance, and cost efficiency. Whether your application requires flexible rubber tubing, industrial rubber tubing, silicone rubber tubing, or rubber tubing for fluid transfer, material quality and proper selection are essential.

Excel Rubber provides dependable, high-performance rubber tubing solutions trusted by U.S. industries for durability, compliance, and long-term reliability.