Industrial rubber products are a silent yet critical part of modern manufacturing and heavy-duty operations. From sealing fluids to absorbing vibration, rubber components help machines function smoothly in demanding environments. However, when these components fail, the impact can be severe—unexpected downtime, costly repairs, safety risks, and lost productivity.

In high-performance applications, rubber components face extreme pressure, temperature changes, chemical exposure, and continuous mechanical stress. Because of this, failure is often not caused by a single factor. Instead, it usually results from a combination of poor material selection, design limitations, and industrial rubber quality issues.

Understanding why rubber components fail and how to select the right high-performance rubber products can help businesses avoid recurring problems. Moreover, working with a reliable custom rubber manufacturer ensures longer-lasting components that perform exactly as intended.

The Importance of Industrial Rubber Products in High-Performance Applications

Industrial rubber products are used across industries such as automotive, aerospace, oil and gas, manufacturing, HVAC, and medical equipment. Their flexibility, resilience, and sealing capability make them ideal for applications where rigid materials fall short.

Some common uses include rubber gaskets, O-rings, seals, hoses, bushings, mounts, and protective covers. These components are expected to perform under constant stress while maintaining integrity over long periods. As a result, even small performance issues can lead to major operational problems.

Therefore, selecting the right rubber components supplier is not just a purchasing decision—it is a long-term reliability decision.

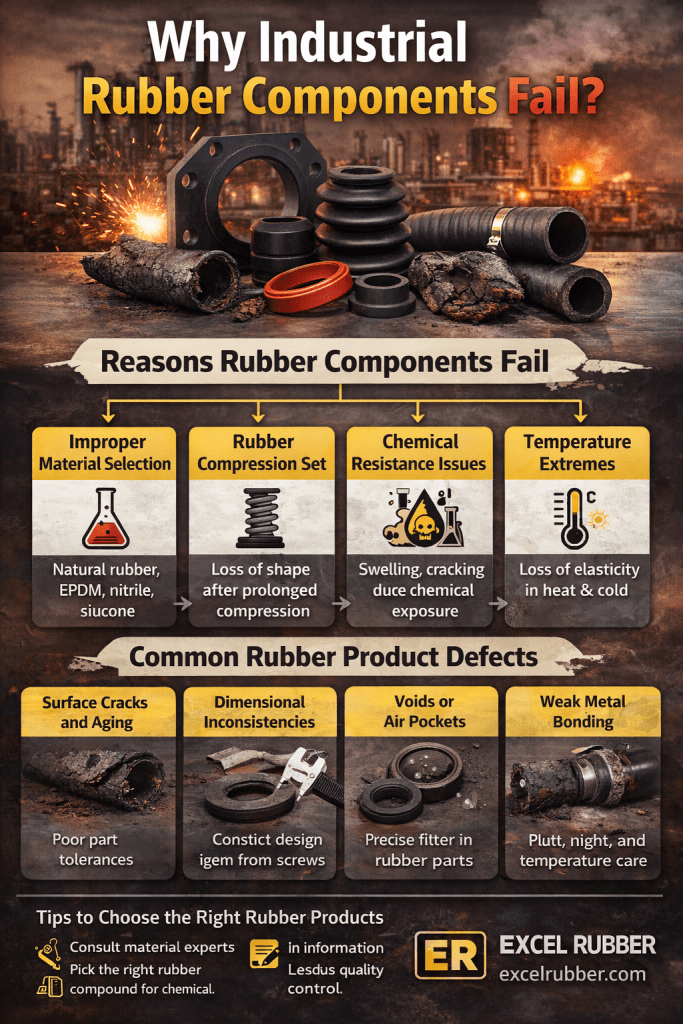

Why Rubber Components Fail in Demanding Environments

Rubber performance problems rarely occur without warning. In most cases, failure begins slowly and worsens over time. Identifying the root causes is the first step toward prevention.

1.Poor Rubber Material Selection

One of the most common reasons industrial rubber products fail is incorrect material selection. Each rubber compound has specific strengths and weaknesses. When a material is used outside its intended environment, performance issues are almost guaranteed.

For example, EPDM rubber performs well outdoors and resists ozone, but it degrades quickly when exposed to oils. Nitrile rubber, on the other hand, resists petroleum-based fluids but performs poorly under constant UV exposure.

Without a proper rubber material selection guide, companies often choose materials based on cost rather than performance. As a result, premature failure becomes unavoidable. This is why partnering with an experienced custom rubber manufacturer is essential for high-performance applications.

2.Rubber Compression Set Problems

Compression set is another major cause of failure. It occurs when rubber remains permanently deformed after being compressed for long periods. Once this happens, the rubber can no longer provide an effective seal or absorb vibration properly.

Compression set problems are especially common in gaskets and seals used in high-pressure systems. Over time, loss of elasticity leads to leaks, pressure drops, and increased wear on surrounding components.

In many cases, compression set is caused by poor compound formulation or incorrect curing during manufacturing. High-performance rubber products are specifically engineered to minimize compression set, even under continuous load.

3.Chemical Resistance Issues

Chemical exposure is unavoidable in many industrial environments. Oils, fuels, solvents, acids, and cleaning agents all interact with rubber differently.

When rubber chemical resistance issues are overlooked, components may swell, soften, crack, or lose tensile strength. These changes weaken the rubber structure and shorten its service life significantly.

Selecting chemically compatible materials requires expert knowledge. For this reason, a knowledgeable rubber components supplier will always evaluate chemical exposure before recommending a compound.

4.Temperature Extremes and Thermal Aging

High temperatures accelerate rubber aging, while extremely low temperatures reduce flexibility. Over time, thermal stress causes rubber to harden, crack, or become brittle.

Thermal aging is one of the most overlooked rubber durability issues. Many failures occur simply because the rubber material was not designed for the actual operating temperature range.

High-performance rubber products are formulated to maintain flexibility and strength across wide temperature ranges. Choosing the right compound dramatically improves long-term performance.

Common Rubber Product Defects That Lead to Failure

Even with the correct material, manufacturing defects can cause early failure. These defects often go unnoticed until the component is placed under real-world stress.

1.Surface Cracks and Premature Aging

A common question many engineers ask is: why do rubber parts crack prematurely? In most cases, cracking is caused by ozone exposure, UV radiation, or inadequate protective additives.

Low-quality rubber compounds often lack stabilizers that slow down aging. Over time, this leads to surface cracking, reduced elasticity, and eventual failure.

2.Dimensional Inaccuracies

Precision matters in high-performance applications. Rubber parts that do not meet exact tolerances may leak, loosen, or wear unevenly.

Dimensional inconsistencies often result from poor tooling or insufficient quality control. A professional rubber parts manufacturer USA uses advanced tooling and strict inspection processes to ensure consistency across production runs.

3.Internal Voids and Weak Points

Air pockets or voids inside rubber components weaken their internal structure. Under pressure, these weak points can collapse or tear.

Such defects are usually caused by improper molding techniques or rushed curing processes. Choosing a reputable rubber manufacturing company significantly reduces the risk of internal defects.

Industrial Rubber Quality Issues That Affect Performance

Quality issues in industrial rubber products are not always visible. However, they can significantly affect performance over time.

1.Inferior Raw Materials

Some manufacturers use recycled fillers or low-grade polymers to reduce costs. While this may lower the price, it also reduces durability, elasticity, and chemical resistance.

High-quality raw materials are essential for long-lasting performance, especially in high-stress applications.

2.Improper Curing Processes

Rubber curing is a precise process. Under-curing results in weak, sticky rubber, while over-curing makes it brittle. Either issue can lead to premature failure.

A reliable custom rubber manufacturer carefully controls curing time and temperature to achieve optimal material properties.

3.Lack of Application-Specific Testing

Without real-world testing, manufacturers cannot accurately predict how rubber components will perform. Testing for compression, temperature, chemical exposure, and abrasion is critical.

High-performance rubber products are always tested under simulated operating conditions to ensure reliability.

Rubber Durability Issues in High-Stress Applications

Durability is not just about material strength. It is also influenced by design, installation, and operating conditions.

Continuous vibration, repeated compression cycles, and environmental exposure gradually weaken rubber components. When durability is overlooked, even the best materials will fail prematurely.

This is why collaboration between engineers and a rubber components supplier is so important. Together, they can design components that withstand real-world stress.

Design-Related Rubber Performance Problems

Material quality alone cannot compensate for poor design. In fact, many rubber performance problems originate during the design stage.

1.Stress Concentration and Sharp Edges

Sharp corners and uneven thickness create stress concentration points. Over time, these areas tear or crack under load.

Smooth transitions and uniform wall thickness significantly improve durability.

2.Incorrect Tolerances

Excessive compression leads to accelerated compression set, while insufficient compression causes leaks. Proper tolerances ensure optimal performance and longer service life.

Custom-designed rubber parts eliminate many tolerance-related issues.

Rubber Material Selection Guide for Industrial Use

Selecting the right rubber material requires careful evaluation of several factors.

1.How to Choose the Right Rubber Material

Before choosing a material, consider the following:

Operating temperature range

Type of chemical exposure

Mechanical load and pressure

Environmental conditions

Regulatory requirements

By analyzing these factors, a custom rubber manufacturer can recommend the most suitable compound for the application.

2.Best Rubber Material for Industrial Applications

There is no universal best rubber material. Each application requires a specific solution.

- EPDM is ideal for outdoor and weather-resistant applications.

- Nitrile performs well in oil and fuel environments.

- Neoprene offers balanced performance across multiple conditions.

- Silicone handles extreme temperatures effectively.

- Viton is excellent for aggressive chemical exposure.

The best choice depends entirely on operating conditions.

Custom Rubber vs Standard Rubber Parts

Standard rubber components are designed for general use. While they may work in basic environments, they often fail in high-performance applications.

Benefits of Custom Rubber Parts

- Custom rubber components offer:

- Improved durability

- Better material compatibility

- Precision dimensions

- Longer service life

A custom rubber manufacturer designs components specifically for your application, reducing failure risks and long-term costs.

Rubber Extrusion vs Molding Differences

Understanding manufacturing methods helps in choosing the right production process.

Rubber Extrusion vs Molding Difference

Rubber extrusion produces continuous profiles with consistent cross-sections, such as seals and strips. It is cost-effective for long lengths.

Rubber molding creates complex shapes with tight tolerances. It is ideal for precision components exposed to high stress.

An experienced rubber components supplier can recommend the best method based on design and performance requirements.

How to Improve Rubber Product Lifespan

Extending the lifespan of industrial rubber products requires a proactive approach.

- Choose the correct material from the start

- Use custom-designed components

- Follow proper installation guidelines

- Perform regular inspections

- Work with a trusted rubber parts manufacturer USA

These steps significantly reduce downtime and replacement costs.

Choosing the Right Rubber Manufacturing Company

The success of any rubber component depends heavily on the manufacturer behind it.

A reliable rubber manufacturing company offers material expertise, custom engineering, advanced testing, and strict quality control. Companies like Excel Rubber provide high-performance rubber products designed to meet demanding industrial requirements.

FAQs: Industrial Rubber Products in Westland

Why do rubber parts crack prematurely in Westland?

Premature cracking is often caused by ozone exposure, temperature fluctuations, or incorrect material selection for local conditions.

How do I choose the right rubber material for industrial use?

Evaluate temperature, chemical exposure, and mechanical stress, then consult a custom rubber manufacturer for expert guidance.

What is the best rubber material for industrial applications?

The best material depends on the application. EPDM, nitrile, silicone, neoprene, and Viton each serve different industrial needs.

How can I improve rubber product lifespan?

Use high-performance rubber products, ensure proper installation, and source components from a reliable rubber components supplier.

Should Westland businesses choose custom rubber over standard parts?

Yes. Custom rubber parts provide better durability, performance, and cost efficiency in high-performance environments.

Conclusion

Industrial rubber products are essential for high-performance applications, yet failures are often preventable. Poor material selection, design flaws, and industrial rubber quality issues are the most common causes of failure.

By understanding why rubber components fail and working with a trusted custom rubber manufacturer, businesses can significantly improve reliability and reduce long-term costs. Choosing high-performance rubber products from a reputable rubber parts manufacturer USA ensures consistent performance, even in the most demanding environments.

1 Comment

Comments are closed.