When it comes to protecting buildings, vehicles, and industrial equipment, window rubber seals play a far more critical role than most people realize. A high-quality window rubber seal blocks water intrusion, reduces air leakage, minimizes noise, and improves overall energy efficiency. In the USA, where windows are exposed to diverse weather conditions—from freezing winters to hot, humid summers—choosing the right sealing material is essential.

This in-depth on-page guide explains everything you need to know about window rubber seals, how they work, why material selection matters, and how custom rubber rectangular strips can solve sealing challenges across residential, commercial, and industrial applications.

What Is a Window Rubber Seal?

A window rubber seal is a flexible rubber component installed around the edges of windows to create a tight barrier between the glass and its frame. It absorbs vibration, compensates for gaps, and prevents external elements such as rain, dust, wind, and noise from entering the interior space.

Unlike rigid materials, rubber adapts to minor movement caused by temperature changes, pressure, or structural shifting. This flexibility makes window rubber seals a long-term sealing solution rather than a temporary fix.

Why Window Rubber Seals Matter in the USA

In the United States, windows face extreme environmental variations. Northern regions experience snow, ice, and freezing temperatures, while southern states deal with intense UV exposure and humidity. Without a reliable window rubber seal, these conditions can quickly lead to leaks, drafts, and structural damage.

A properly designed window rubber seal offers:

- Long-term weather resistance

- Improved insulation and energy efficiency

- Reduced HVAC load and lower energy bills

- Protection against water damage and mold growth

- Enhanced comfort and noise reduction

For manufacturers and contractors, rubber window seals also ensure compliance with building standards and performance expectations.

Common Applications of Window Rubber Seals

Window rubber seals are used across multiple industries in the USA, each with unique requirements:

Residential Windows

Homeowners rely on window rubber seals to stop air leaks, prevent water infiltration, and maintain indoor comfort throughout the year. They are commonly used in sliding windows, casement windows, and fixed glass panels.

Commercial Buildings

Office buildings, hospitals, schools, and retail spaces require heavy-duty window rubber seals that can withstand frequent temperature changes and long operating hours while maintaining airtight performance.

Automotive & Transportation

In vehicles, window rubber seals reduce wind noise, prevent water leaks, and support passenger safety. They must endure vibration, UV exposure, and frequent movement without cracking.

Industrial & OEM Applications

Machinery enclosures, control panels, and equipment windows rely on custom rubber rectangular strips for precise sealing and long service life.

Types of Window Rubber Seals

Choosing the right type of window rubber seal depends on the application, environment, and performance requirements.

EPDM Rubber Window Seals

EPDM rubber is one of the most popular materials for window sealing in the USA. It offers excellent resistance to UV rays, ozone, moisture, and temperature extremes.

Silicone Rubber Window Seals

Silicone seals are ideal for high-temperature or medical environments. They remain flexible over a wide temperature range and resist aging.

Neoprene Rubber Seals

Neoprene provides good oil resistance and durability, making it suitable for industrial and automotive window sealing.

Rubber Rectangular Strip Seals

Rectangular rubber strips are highly versatile and commonly used where uniform compression and simple installation are required. They can be cut to length and adapted to custom window designs.

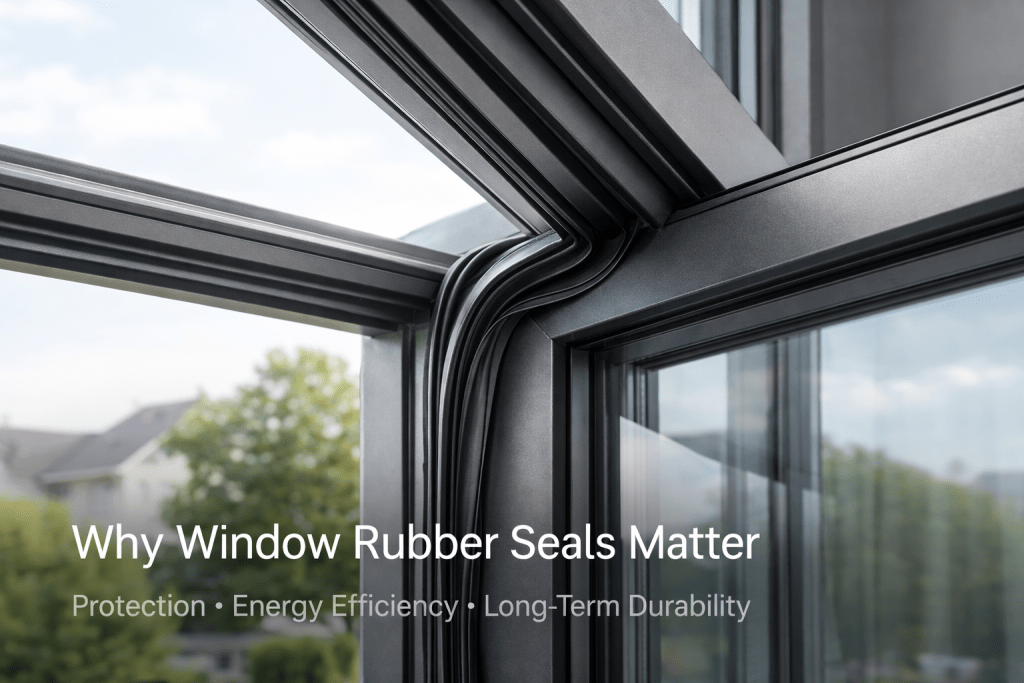

Benefits of Using Rubber Rectangular Strips for Window Sealing

Rubber rectangular strips are widely used for window rubber seals due to their simplicity and effectiveness. Key advantages include:

- Consistent sealing pressure across the window frame

- Easy customization for different window sizes

- Excellent compression set resistance

- Compatibility with various frame materials

- Cost-effective solution for OEM and retrofit projects

These strips are especially valuable in projects where precision and repeatability are critical.

Material Properties That Define a High-Quality Window Rubber Seal

A durable window rubber seal must meet specific material performance standards:

Flexibility

The seal must compress easily without tearing and return to its original shape once pressure is released.

Weather Resistance

Exposure to rain, snow, sunlight, and pollution should not cause cracking, shrinking, or hardening.

Thermal Stability

High-quality rubber maintains its properties across a wide temperature range.

Chemical Resistance

In industrial or urban environments, seals may encounter oils, cleaners, or airborne chemicals.

How Custom Window Rubber Seals Solve Real-World Problems

Standard, off-the-shelf seals may not always provide a perfect fit. Custom window rubber seals address issues such as:

- Irregular window dimensions

- Non-standard frame designs

- Specialized compression requirements

- Long-term durability concerns

Custom rubber rectangular strips can be engineered to precise tolerances, ensuring optimal performance and extended service life.

Window Rubber Seal Installation Best Practices

Correct installation is just as important as material selection. To achieve the best results:

- Clean the window frame thoroughly before installation

- Measure accurately to avoid gaps or over-compression

- Use compatible adhesives or mechanical retention systems

- Avoid stretching the rubber during installation

- Inspect seals periodically for wear or damage

Proper installation significantly increases the lifespan of window rubber seals.

Signs You Need to Replace Your Window Rubber Seal

Even the best seals wear out over time. Common indicators include:

- Visible cracks or hardening

- Water leaks during rain

- Drafts or temperature fluctuations

- Increased exterior noise

- Mold or condensation around window edges

Replacing worn window rubber seals early prevents costly structural damage.

Sustainability & Energy Efficiency Benefits

Modern window rubber seals contribute to sustainability by improving insulation and reducing energy loss. In the USA, energy-efficient buildings are increasingly important due to rising energy costs and environmental regulations.

A well-sealed window:

- Lowers heating and cooling demand

- Reduces carbon footprint

- Enhances building performance ratings

- Supports green building initiatives

Why Manufacturers and Contractors Choose High-Quality Rubber Seals

For professionals, reliability is non-negotiable. High-performance window rubber seals reduce callbacks, improve customer satisfaction, and ensure compliance with quality standards.

Rubber rectangular strips designed for window sealing offer consistency, scalability, and adaptability across multiple projects.

Trending FAQs About Window Rubber Seals (USA)

What is the best material for a window rubber seal?

EPDM rubber is widely considered the best choice in the USA due to its resistance to UV rays, moisture, and extreme temperatures.

How long do window rubber seals last?

High-quality window rubber seals can last 10–20 years depending on material, exposure, and installation quality.

Can window rubber seals improve energy efficiency?

Yes. Proper sealing reduces air leakage, helping maintain indoor temperatures and lowering energy bills.

Are rubber rectangular strips suitable for window sealing?

Absolutely. Rubber rectangular strips provide uniform compression and are ideal for custom or non-standard window designs.

Do window rubber seals prevent noise?

Yes. They help dampen vibrations and reduce outside noise, especially in urban or high-traffic areas.

Can window rubber seals be used outdoors?

Outdoor-grade rubber seals, especially EPDM, are designed to withstand weather exposure and UV radiation.

How do I know which window rubber seal I need?

Selection depends on window type, frame material, exposure conditions, and compression requirements.

Are custom window rubber seals worth it?

Custom seals ensure a precise fit, better performance, and longer lifespan, making them cost-effective in the long run.

Choosing the Right Window Rubber Seal for Your Project

Selecting the right window rubber seal is about balancing performance, durability, and cost. Whether you need a simple rectangular strip or a fully custom profile, the right rubber solution ensures long-term protection and efficiency.

For projects across the USA—residential, commercial, automotive, or industrial—investing in high-quality window rubber seals delivers measurable benefits in comfort, safety, and performance.

To make the correct choice, several key factors must be evaluated carefully. These include the application environment, material compatibility, seal profile, compression requirements, and expected lifespan. Understanding these elements helps ensure the window rubber seal performs exactly as intended under real-world conditions.

1. Understand the Application Environment

The first step in choosing the right window rubber seal is identifying where and how it will be used.

In residential applications, seals must provide strong insulation against outdoor temperatures, rain, wind, and noise. In commercial buildings, seals are often exposed to higher usage, pressure differentials, and stricter building codes. Industrial and OEM applications may require seals that withstand vibration, chemicals, or repeated mechanical stress.

In the USA, climate plays a major role. Window rubber seals used in colder regions must remain flexible in freezing temperatures, while seals in warmer states must resist UV exposure and ozone without cracking or shrinking. Evaluating environmental conditions upfront prevents premature seal failure.

2. Choose the Right Rubber Material

Material selection directly impacts durability and performance.

EPDM rubber is widely preferred for window rubber seals due to its excellent resistance to weather, UV radiation, moisture, and temperature extremes. This makes it ideal for most outdoor window applications across the United States.

Silicone rubber is often selected when extreme temperature resistance or long-term flexibility is required. It performs well in high-heat environments but may come at a higher cost.

Neoprene rubber offers balanced resistance to oils and environmental exposure, making it suitable for specific industrial or automotive window sealing needs.

Matching the rubber compound to the operating environment ensures the seal maintains elasticity and sealing pressure over time.

3. Select the Proper Seal Profile and Shape

Window rubber seals come in various shapes and profiles, each designed for specific sealing challenges.

Rubber rectangular strips are one of the most versatile options. They provide uniform compression, are easy to install, and work well in both standard and custom window designs. Their simple geometry makes them ideal for projects requiring consistent sealing across flat surfaces.

Other profiles may be required for channels, grooves, or irregular window frames. However, rectangular rubber strips are often preferred for retrofit projects and OEM applications where flexibility and adaptability are critical.

Choosing the correct profile ensures the seal fits securely without excessive force or deformation.

4. Consider Compression and Tolerance Requirements

Compression is a crucial factor in window rubber seal performance. The seal must compress enough to block air and water without being overstressed.

Too little compression results in gaps and leaks. Too much compression can cause permanent deformation, reducing the seal’s lifespan.

High-quality rubber rectangular strips are engineered to maintain shape and elasticity even after repeated compression cycles. Understanding the required compression range helps prevent installation issues and ensures consistent sealing over time.

Tolerance control is equally important in applications where precision matters, such as commercial glazing systems or industrial equipment windows.

5. Evaluate Installation Method and Maintenance Needs

Ease of installation is often overlooked but can significantly affect project timelines and costs.

Some window rubber seals are designed for adhesive bonding, while others rely on mechanical retention or pressure fitting. Rubber rectangular strips are particularly installation-friendly, as they can be cut to length and installed with minimal tools.

Maintenance requirements should also be considered. High-quality rubber seals require little upkeep beyond routine inspection. Selecting durable materials reduces the need for frequent replacements and lowers long-term maintenance costs.

6. Balance Performance, Longevity, and Cost

While initial cost is always a consideration, focusing solely on price can be misleading. Low-quality window rubber seals may fail quickly, leading to higher replacement and repair expenses.

Investing in durable rubber seals offers better long-term value by reducing energy loss, preventing water damage, and minimizing downtime. For manufacturers and contractors, reliable seals also reduce callbacks and warranty claims.

Rubber rectangular strips provide an excellent balance between affordability, performance, and customization, making them a popular choice for both large-scale and specialized projects.

7. Opt for Custom Solutions When Needed

Not all windows follow standard dimensions. Custom window rubber seals are often the best solution for non-standard frames, specialized equipment, or unique architectural designs.

Custom rubber rectangular strips can be manufactured to precise dimensions and material specifications, ensuring optimal fit and performance. This level of customization eliminates guesswork and enhances sealing efficiency.

For projects requiring consistency across multiple units, custom seals also improve scalability and repeatability.

Why the Right Choice Matters

Choosing the correct window rubber seal directly impacts building performance, comfort, and durability. A well-matched seal protects against environmental stress, improves energy efficiency, and extends the life of the window system itself.

By carefully evaluating application needs, material properties, and installation requirements, you can select a window rubber seal that delivers reliable results for years to come—whether for residential homes, commercial buildings, or industrial applications across the USA.

Final Thoughts

A window rubber seal may seem like a small component, but its impact is significant. From protecting against harsh weather to improving energy efficiency and comfort, the right seal makes all the difference.

By choosing durable materials, proper profiles, and precise manufacturing, window rubber seals provide reliable performance for years to come. For applications requiring consistent sealing and adaptability, rubber rectangular strips remain one of the most trusted solutions in the industry.