Introduction

Choosing the right rubber product for your application is not just about finding something that fits; it’s about ensuring optimal performance, longevity, and cost-effectiveness. In this comprehensive buyer’s guide, we aim to equip you with the knowledge and insights needed to make informed decisions. From understanding the intricacies of different rubber properties to evaluating brands and suppliers, we’ll cover all aspects to help you navigate the world of rubber products effectively.

Table of Contents

What is a Rubber Product?

Rubber products constitute a vast array of items crafted from natural rubber, synthetic rubber, or a combination of both in rubber composites. These products serve diverse purposes across industries, boasting unique properties like elasticity, resilience, and insulation. From everyday items like rubber bands and erasers to critical components in automotive, aerospace, and medical sectors, rubber products are indispensable in modern manufacturing and technology.

Importance of Choosing the Right Rubber Product

The significance of selecting the appropriate rubber product cannot be overstated. It directly influences functionality, safety, and overall performance in various applications. Imagine using a rubber seal that cannot withstand environmental conditions or a rubber hose that succumbs to chemical exposure – the consequences can range from inefficiency to catastrophic failure. By choosing the right rubber product, you ensure compatibility with your application’s requirements, leading to enhanced durability, efficiency, and cost-effectiveness in the long run.

Understanding Rubber Properties

Rubber properties such as durability, flexibility, and resistance form the cornerstone of suitability for diverse applications. Let’s delve deeper into each of these key properties to grasp their significance in selecting the right rubber product.

Durability

The durability of a rubber product is its ability to withstand wear, tear, and environmental factors over time. This durability factor is crucial, especially in industries where reliability and longevity are paramount. For instance, in the automotive sector, durable rubber components like engine mounts and gaskets ensure optimal performance and minimal downtime. Manufacturers achieve durability through precise material formulations, reinforcement techniques, and quality control measures, ensuring that the rubber product maintains its integrity under challenging conditions.

Flexibility

Flexibility in rubber products refers to their capacity to deform under stress and return to their original shape. This property is vital in applications involving dynamic movements, vibrations, and mechanical stresses. For example, rubber hoses used in hydraulic systems need to flex without rupturing or losing functionality, showcasing the importance of flexibility. Advanced rubber technologies have expanded flexibility options, allowing for custom solutions tailored to specific flexibility requirements across industries.

Resistance

Rubber’s resistance to various elements such as chemicals, oils, abrasions, and extreme temperatures defines its suitability for specific environments and applications. For instance, rubber seals in industrial machinery must resist oil and chemical exposure to maintain effective sealing properties. Understanding the required resistance levels is crucial in selecting the right rubber product that can withstand environmental challenges without compromising performance or safety.

Types of Rubber Products

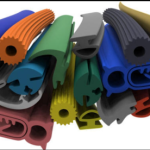

The diversity in rubber products stems from the distinctions between natural rubber, synthetic rubber, and rubber composites. Each type offers unique properties and advantages, catering to different application needs and industry requirements.

Natural Rubber

Derived from latex, natural rubber boasts exceptional elasticity and resilience, making it ideal for applications requiring high tensile strength and durability. Its molecular structure provides inherent properties that are difficult to replicate, making it a preferred choice in specific industries like automotive and construction.

Synthetic Rubber

Synthetic rubber variants such as Styrene-Butadiene Rubber (SBR), Nitrile Rubber (NBR), and Ethylene Propylene Diene Monomer (EPDM) offer specialized properties like oil resistance, weather resistance, and thermal stability. These synthetic rubbers expand application possibilities, particularly in sectors where natural rubber may not meet specific requirements or environmental conditions.

Rubber Composites

Combining multiple rubber types or incorporating reinforcements like fibers or fillers enhances performance and customizability in rubber composites. This approach allows manufacturers to fine-tune properties such as strength, flexibility, and chemical resistance, catering to a wide range of applications across industries.

Applications and Environments

Rubber products find extensive use across various industries and environments due to their versatile properties and functional benefits. Let’s explore some key sectors where rubber products play pivotal roles:

Automotive Industry

Rubber components are integral to the automotive sector, contributing to safety, comfort, and performance in vehicles. From tires and seals to vibration dampeners and engine mounts, rubber products ensure smooth operations and durability in diverse driving conditions.

Industrial Machinery

Rubber parts play vital roles in machinery and equipment across industries, offering sealing solutions, shock absorption, and noise reduction. Whether in manufacturing plants, processing facilities, or construction sites, rubber components enhance operational efficiency and equipment longevity.

Blended Sponge Rubber

Semi sponge elastomer is essentially a mixture of different types of rubbers to get the required properties of resilience, durability, flexibility and cost effectiveness. It is applied in a wide range of fields where the integration of various properties into a universal one is provided.

Consumer Goods

Rubber-based materials are ubiquitous in consumer goods, enhancing product durability, aesthetics, and user experience. From footwear and electronics to household appliances and sporting goods, rubber products contribute to everyday comfort and functionality.

Factors to Consider

When choosing rubber products for specific applications, several factors must be carefully evaluated to ensure compatibility, longevity, and optimal performance. Let’s explore these key factors in detail:

Temperature Range

The operating temperature range directly impacts the choice of rubber materials, as different rubber types exhibit varying temperature resistances. Understanding the temperature requirements of your application ensures that the selected rubber product maintains its properties and functionality under extreme heat or cold conditions.

Chemical Compatibility

Assessing the exposure to chemicals, oils, solvents, and environmental elements is crucial in determining the chemical resistance required for optimal performance. Compatibility with specific substances prevents degradation, swelling, or chemical reactions that could compromise the rubber product’s integrity.

Mechanical Stress

Evaluating mechanical stresses such as pressure, impact, and friction helps in choosing rubber products capable of withstanding these forces without deformation or failure.

Understanding the mechanical demands of your application ensures that the selected rubber product maintains structural integrity and performance under stress.

Comparing Brands and Suppliers

Selecting reputable brands and reliable suppliers is essential for obtaining high-quality rubber products and satisfactory customer experiences. Let’s delve into the key considerations when comparing brands and suppliers:

Reputation

Choosing reputable brands known for consistent quality, reliability, and innovation inspires confidence in the performance and durability of the rubber products. Reputable brands often invest in research, development, and quality assurance processes to deliver superior products that meet industry standards and customer expectations.

Quality Standards

Verifying adherence to industry standards, certifications, and quality control measures is crucial in ensuring that the rubber products meet required specifications and performance benchmarks. Suppliers with recognized quality standards instill trust and reliability in their products, leading to long-term satisfaction and operational excellence.

Customer Support

Opting for suppliers offering comprehensive customer support, technical assistance, and after-sales services is vital for addressing any issues or queries promptly. Effective customer support enhances the overall purchasing experience and ensures that customers receive timely assistance and solutions when needed.

Choosing the Right Rubber Product for Your Application

To select the ideal rubber product, it’s essential to assess specific needs, explore customization options, and balance cost considerations for optimal value and performance. Let’s break down these crucial steps in choosing the right rubber product:

Assessing Specific Needs

Identifying critical requirements such as temperature resistance, chemical compatibility, hardness levels, and sealing capabilities based on application demands is the first step in selecting the right rubber product. Conducting a thorough assessment ensures that the chosen product meets all essential criteria for optimal performance and longevity.

Customization Options

Exploring customization services for tailored rubber solutions, including material formulations, dimensions, tolerances, colors, and surface finishes, allows for precise alignment with specific application requirements. Customization options empower customers to fine-tune rubber products to suit unique operational needs, enhancing functionality, and performance.

Cost Considerations

While quality and performance are paramount, considering cost factors is essential to ensure affordability and long-term value. Evaluating upfront costs, lifecycle costs, maintenance requirements, and potential savings from durable, high-performance rubber products enables informed decision-making that aligns with budgetary constraints without compromising quality or functionality.

Important Queries on Rubber Product Selection

Rubber hardness, measured on the Shore durometer scale, depends on factors such as the application’s pressure, stress levels, and environmental conditions. Consulting with experts or using hardness testing tools can provide accurate assessments to determine the ideal hardness level for your specific application needs.

Silicone rubber finds extensive use in medical devices, kitchenware, seals, gaskets, and electronics due to its biocompatibility, temperature resistance, flexibility, and durability. Its versatile properties make it suitable for a wide range of applications across industries.

Protecting rubber products from UV exposure, extreme temperatures, harsh chemicals, and mechanical abuse is crucial to prevent degradation. Regular maintenance, proper storage practices, and using protective coatings or additives can significantly extend the lifespan of rubber products.

Yes, there are eco-friendly rubber alternatives such as recycled rubber, bio-based rubber, and sustainable manufacturing practices that promote environmental conservation and reduce carbon footprint. These options align with sustainability goals while offering performance and functionality.

Certain rubber formulations, such as silicone rubber and fluorocarbon elastomers, exhibit exceptional temperature resistance, spanning from extreme cold to high heat environments without losing their properties or functionality. It’s crucial to select the appropriate rubber type based on the specific temperature range your application demands.

The lifespan of rubber products varies widely based on factors such as material quality, usage conditions, maintenance practices, and exposure to environmental elements. High-quality rubber products designed for their intended purpose and properly maintained can last anywhere from several years to decades.

In conclusion, choosing the right rubber product for your application requires a comprehensive understanding of rubber properties, careful evaluation of application needs, exploration of customization options, consideration of cost-effectiveness, and reliance on reputable suppliers. By following these guidelines and leveraging expert insights, you can make informed decisions that optimize performance, durability, and value across various industries and environments.