Rubber molded products have found their wide range of applications in the entire industries for their multiple benefits such as versatility, longevity and good efficiency. From O-rings to rubber vacuum cups every product of this category performs a vital function of blocking, absorbing, covering to improve diverse used products. This blog will cover all the different aspects and applications of the rubber molding process, its producing techniques, advantages, and future prospects, demonstrating the key role of rubber injected products in contemporary engineering design and production.

Understanding Rubber Molded Products

Molded rubber products represent the overall category of products, having been sculpted or molded from a rubber material. Manufacturers can produce the most complicated parts, the only limit being the imagination, hence, they can fully meet the needs of a wide range of industries. Rubber molding applies to all the sectors automotive, aerospace, medical, and machinery whether to seal the tight components, dampening or to just protect machines and equipment.

There are different types of rubber molded product applications, especially in industries that involve regular contact with hazardous or harsh environments.

O-rings are the critical sealing elements, which are commonly in the form of circular seals made of rubber, for preventing leakage of fluids and gasses in fluid or gas systems. They are not limited only in hydraulic systems, pneumatic systems, and automotive engines which are used to create a tight seal and terminate any leak of fluid or gas.

Disposable rubber grommets are designed for their parts to reduce vibration, cushion for impacts, and absorb shock in machines and devices. They are good examples for noise abatement and stabilization. This is usually achieved by windmills, suspenders, vehicle motors, and industrial machines.

The rolls of a rubber molded shape are quite vital in the printing machinery to ensure swift paper feeding in a uniform manner. These components guarantee even printing by gripping the paper and maintaining proper tension on the printed material by keeping the paper from sliding.

Vibration mounts, also known as vibration insulators, are implemented to prevent the propagation of shocks and vibrations during the operation of different kinds of machineries and devices. They safeguard delicate parts from excessive impact variances thus resulting in much better performance and extended life of the equipment.

Vacuum cups or suction cups made of rubbers are commonly used in material handling, packaging and robotic operations. The robotic hand gripper recreates a sucking effect when it is in contact with the surface for lifting and electricity, or gas to provide the motion needed to manipulate objects precisely and with control.

Rubber bellows are designed as flexile folds covers or seals to secure moving parts from dust, debris, contaminants, and surrounding conditions. They are made of braided metal springs, which prevent during compression, thereby ensuring the seal of technics that undergo full amplitude environmental load.

Rubber grommets widely used for wire and cable management, vibration damping and sealing applications (wire and cable management, vibration dampening and sealing applications). They provide insulation, minimize chafing and noise and vibration are also reduced in electrical systems, automotive elements and mechanical equipment.

On one hand, products molded by the different types of rubber have different uses across various industries and, on the other, the rubber materials perform marvelous duties in fulfilling the engineering requirements and manufacturing needs which are tailor-made without fail.

Applications Across Industries

The versatility of rubber molded products enables their widespread use across a range of industries:The versatility of rubber molded products enables their widespread use across a range of industries:

Automotive Sector

The auto industry rubber molded products comprising business O-rings, seals, gaskets, etc are employed in engines, transmission systems, braking systems and fluid handling systems. These components make sure that there is no leakage, proper vibration elimination, and good thermal isolation, thus leading to a better performance, safety, and reliability of a vehicle.

Aerospace Industry

In the field of aerospace, compound rubbers find their applications as seals, gaskets, shock absorbers, vibration absorbers, as well as structure components of aircraft engines, hydraulic systems and landing gears assemblies. They are designed to withstand extreme temperatures, pressures and harsh conditions like heat flux, vibration, and over-pinging; hence they are key to flight safety and mission performance.

Medical Equipment

Molded rubber parts are important in any case when manufacturing medical devices and equipment such as seals, gaskets, tubing and special instruments for diagnostic tools, general surgery equipment, and the patient care devices. Hence, they are compatible, do not allow bacteria to grow or else get contaminated, and the final product gives the most accurate shape. They meet the most stringent regulations set by the health sector and the industry.

Industrial Machinery

Rubber products molded into the shapes they need enjoy the widest applications in industrial machinery production, especially for sealing, damping, protecting and improving performance of industrial equipment. Their presence in industrial applications such as seals, gaskets, connectors, mounts and custom molded products could be found in almost all of the major manufacturing industry, construction, energy and automation sectors.

These rubber molded products find use in a variety of applications and are essential, not only in ensuring efficient, safe, and reliable industrial solutions but also in reducing expenses and cutting down waste.

Manufacturing Processes

The manufacturing of rubber molded products involves several processes tailored to achieve precise shapes, sizes, and properties:

Compression Molding: Compared to compression molding, which is a commonly used method for manufacturing rubber molded items, is another method. It has an essence involving the introduction of the rubber compound into a heated mold cavity and applying a force both to compress and shape the material. The production technique allows for large-scale complex parts manufacturing ranging from simple to moderately complex parts.

Injection Molding: The injection molding will involve the molding of the rubber complexity and the tight tolerance. The technique involves injection of molten rubber into the mold cavity under strong pressure which gives the part dimensional control and which even allows to achieve the details of the form . Injection molding is frequently chosen for precision components with crossed geometrical cross-sections.

Transfer Molding: The use of transfer molding combines advantages from both compressed molding and injection molding. It is a process in which automatically fed rubber pieces are heated and transferred to a closed mold cavity under high pressure. In the mold cavity, a vulcanization process enhances the strength and flexibility of the rubber material. Transfer molding, being true for part production with complex design and fine finishes, is unlike any other process with uniformity.

The choice of a manufacturing process occurs due to the different benefits of the manufacturing process. Factors such as the level of complexity, the quantity of production, the material properties, and the required results determine the selection of a manufacturing process.

Rubber molding products are uncomplicated, and their components can be easily removed and replaced.

Rubber molded products offer several advantages that make them indispensable in various industries:

Excellent Sealing Capabilities: The form of rubber products offer proper sealing solutions against various detergents moisture, gasses, and pressure. This results in airtight seals that establish barriers against different gas leakages, contaminations, and environmental ingress as well. Therefore, the systems and equipment’s safety and reliability are secured because of this.

Customization and Versatility: Molding rubber enables designers to create products of different size, contour, hardness and material—at their own discretion. Through such versatility the compliance with enforceable constraints of certain types of missions and applications may also be achieved, apart from special requirements with regard to the engineering and performance.

Durability and Resilience: Rubber “stamped” items possess exceptional strength, elasticity and resistance against damage by friction, heat, chemical agents, and other negative factors. They carry their structural integrity and sealing properties over long spans of time, cutting down on the needs for frequent maintenance as well as repairing down time.

Cost-Effectiveness: Production process optimization, solidity in timeline, and less maintenance are what make rubber molded products cost-effective. They ensure a long-term profitability thanks to the lower amount spent on replacement parts, uninterrupted workflow, and no downtime.

Quality Control and Testing

Quality control measures and testing are essential aspects of rubber molding processes to ensure the performance, reliability, and safety of molded products:

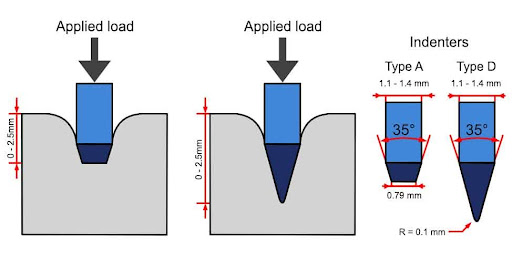

Hardness Testing: Evaluation of the hardness of rubber materials by using durometers, which establish the deflection or compression properties.

Compression Set Testing: Investigational and deformation assessment of rubbers in shaping and returning to the initial shape, signaling their sealing and durability capability.

Material Compatibility Testing: Carrying out a compatibility test with rubber components and different liquids, chemicals and environmental influences to prove their durability and reserves against failure.

Our quality control standards start with comprehensive monitoring of raw materials usage, closely tracking the production process, and performing audits of finished products to guarantee compliance with the industry standards and customer requirements.

Environmental Sustainability

Rubber molded products contribute to environmental sustainability through:Rubber molded products contribute to environmental sustainability through:

Eco-friendly Materials: Use of sustainable rubber materials including the ensured use of recycled rubber and bio-based compounds diminish the draw from virgin sources and has a great impact on promoting the circular economy concept.

Recycling Initiatives: Further specifically, recycling programs for rubber materials and rubber end of life products seek to minimize waste disposal, conserving resources by reducing overall environmental impact.

Green Manufacturing Practices: Implementation of energy saving methods, waste diminishing tactics, climate friendly industrial technologies will not only save our environment but also decrease the production of greenhouse gasses.

Obviously, firstly the industry is eco-friendly because they use recycling initiatives and green manufacturing practices. This industry helps in positively aiding environmental sustainability by responsible resource management.

Challenges and Solutions

Challenges in rubber molding processes include:Challenges in rubber molding processes include:

Mold Design Complexity: Molding of complex 3D shapes, finer details, or higher dimensional accuracy is a challenge which requires complex design and is needed for an accurate and quality tooling.

Material Selection: As a specific part to this, optimum composition of a rubber compound including necessary hardness, resilience, chemical resistance, and temperature tolerance is the critical determinant of durability for the performance.

Dimensional Accuracy: Achieving accurate molding and similitude in dimension across manufacture orders is important as it makes parts c0mpatible and simple to assemble.

Solutions to these challenges involve:

Advanced Tooling Technologies: CAD/ CAM ‘s sophisticated software, combined with the application of CNC machining and 3D printing for mold fabrication and design to come up with extremely intricate dimensions and tolerances.

Material Testing and Optimization: Material testing in full detail, formulation improvement, and performance assessment to determine the ideal down-rubber compound for each application.

Quality Assurance Processes: Deploying well defined quality control practices like immediate monitoring operate and process statistics is the key to maintain the dimensional accuracy, product consistency, and the specifications.

Through the active consideration of these issues and consequent execution of appropriate measures manufacturers may reach – the determination of beneficial output from the molding of raw materials.

Future Trends and Innovations

Advanced Materials: Innovative rubber compounding technologies, nano-material and combining polymer technology of performance, durability, and functionality with research and development.

Industry 4.0 Integration: Application of digital technologies, automation, robotics, and data analytics in rubber molding processes for envisaged benefits like improved accuracy, productivity, and quality control.

Smart Manufacturing: Attributes of IoT (Internet of Things) sensors, predictive maintenance, and real-time control instruments that help smart manufacturers to apply predictive analysis, and proactive quality control.

These trends and innovations are to propel the sector of rubber molding, with there being developments in materials science, production efficiency, product customizations, and sustainability among the many that are anticipated.

Conclusion

Summing up, the study of rubber molded goods sheds light on their vital significance to the assembly of various engineering, manufacturing and application areas. Whether they are used for the purpose of O-rings or printer rollers, they provide world-class sealing and dynamic capabilities, together with other qualities, such as the option of personal customization, robustness, and environmental sustainability.

Accomplished via highly advanced technologies and superior quality controls, rubber moldings break through the barriers and assure dependable performance in different industries.

While industry changes in line with future trends and innovations are implemented, rubber molding is a dynamic process that is capable of adjusting itself to diversified customer requirements and green initiatives while at the same time taking care of the environment.

This perspective is the summary of the role of rubber molded products in the creation of better sealing solutions, reduction of operational costs, and enhancements of productivity that leads to technological developments that are being used in different fields of trade.