These gaskets are the lifeblood of the equipment in different operational sectors that contribute greatly to the overall efficiency and the long operational life of the machines. These highly customized splines perform several jobs , keeping the tightness unharmed and adapting to the environment, assuring maximum operational performance regardless of the situation. The fact that custom rubber gaskets and their purpose & advantages are understood by all business operators is thus critical for them in order to achieve the maximum equipment performance with absolute minimum downtime.

Introduction to Custom Rubber Gaskets

Rubber gaskets are specialized seals that are able to twist and stretch to seal tight fitting joints and prevent leakages. These materials are commonly used for instance, silicone, EPDM, neoprene and nitrile rubber. Ersatz rubber gaskets are specially made to fit the exact needs of the machine and enable the best possible performance and lifetime for those machines. Such gaskets are essential for making sure of new fitting joints, avoiding household fluid or gas leakage, as well as the components within from the outside elements.

Custom rubber gaskets carry their own benefits over the standard gaskets among which superiority in durability, fitting assurance and exposure to outside environment are the top advantages. The customized design of gaskets allows the manufacturers to make the seals of sizes, shapes & material composition which exactly fits to the individual needs for perfect fitment. As a result, the effectiveness & reliability of the seals is maintained.

Table of Contents

Importance of Custom Rubber Gaskets in Equipment Performance

Seal Integrity

Specially customized rubber gaskets form an unremovable seal across mating surfaces that keep gas or fluid from leaving. This seal integrity is crucial for places or tools that may cause problems like equipment malfunctions or environmental risks if they leak. Custom gaskets help to seal engines in cars and machines in industries, basing on their individual properties, as well as to prevent leaks. This helps to secure reliable performance and reduces the wastage of money.

Vibration Dampening

Rubber gaskets operate to neutralize vibrations occurring within equipment during operation thereby noise reduction and preservation of the component parts from the effect of wear and tear on them. This resultant reduction in wear-and-tear allows prolonged lifespan of machinery and also adds value to performance. In applications in which too many vibrations can destabilize the functioning of items or result in them getting damaged is where custom rubber gaskets result in efficient protection as well as operation resulting in quiet, smooth operations.

Temperature Resistance

Thanks to their durability, custom rubber gaskets are able to operate in extreme temperature ranges that encompass such an operating environment. They can withstand exaggerated temperatures be that hot or cold without losing their sealing integrity. This temperature resistance is an important characteristic in areas such as aviation, car construction, and production, where the techniques can be used under extreme conditions.

Customization Options for Rubber Gaskets

Materials

Different from the others, the rubber gaskets are offered in an array of materials, and each of their properties, including the chemical resistance, flexibility and wideness, is special. The material you choose determines how suitable it will be in light of your intended application as well as the operating conditions Thermal efficacy is one of the reasons why silicone rubber is often the choice of material. EPDM rubber, on the other hand, is sought after because of its superlative resistance to weathering and UV rays.

Size and Shape

Custom rubber gaskets can be manufactured in the most different form and size, even the most unique of them for the purpose of fitting the various equipment configurations. The tailor is made to give the most suitable fitting as well as maximum sealing. It can be round or rectangular, flat, or irregularly shaped, but a customized gasket is always the best remedy for sealing and isolation against leaks and pollutants.

Thickness and Durometer

Thickness and durometers (hardness) are customizable allowing for proper compression and sealing. The gaskets are thicker as they deliver the compression, while the durometer controls flexibility and reliability. Filtration is provided and selected suitable thickness as well as durometer for each application purpose which will in turn help with the enhancement of seal function. Seal life will also be extended.

Excel Rubber Sponge Gaskets

We at Excel Rubber have the whole range of services which are available in extruded products, molded products, and sponge products for industries that need them. Our range of sponge seals includes but is not limited to Excel Sponge Rubber Gasket and Excel Neoprene Sponge Gasket which are remarkable for suppressing the compression set and sealing the gap.

The engineering of such sponge gaskets is done to ensure lasting performance under extreme conditions in the markets like the automotive, aerospace and electronic sectors. Specifically, our sponge gaskets, due to their unique resistance to compression set and high sealing quality, will perform steadily in different conditions. A high-quality approach and innovation of Excel Rubber allow us to become the ultimate partner for those businesses, who on the market search for sealing solutions of the highest level.

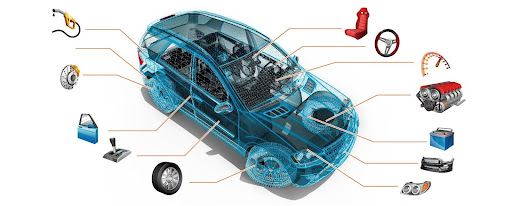

Applications of Custom Rubber Gaskets

– Automotive Industry: Sealing engine components, fuel systems, and HVAC systems(Heating, Ventilation and Air Conditioning Systems).

– Aerospace Industry: Ensuring efficiency of sealing engine and fluid systems extended to air and fluids.

Custom rubber gaskets are key components in every one of these industries when it comes to ensuring reliable operations, safety, and performance. While used in automotive engines, aircraft body and electronic enclosure seals are most frequently applied to resist the above-listed conditions and make the operation perfect.

Advantages of Using Custom Rubber Gaskets

Enhanced Equipment Reliability

The custom rubber gaskets make the seal firm and therefore reduces the chance of leaking including equipment failure, therefore the total reliability and uptime. In instances where downtime can turn out to be prohibitive or catastrophic, these seals are offering the needed protection and, therefore, a continuation of operation.

Improved Safety

Sealing critical facets of the machines with the custom gaskets to avert the leaks of hazardous materials or failures due to faulty gaskets is a surefire way to provide a safe working and living environment for everyone involved. In workplaces where ordinary- coating material, oils or gas fluids, or extreme high and low temperatures are involved, the custom-made rubber gaskets are designed to enable safety and decrease risks of possible accidents or injuries.

Cost Efficiency

Specialized synthetic and rubber ring seals for equipments perfect operation by minimizing their need of repair and replacement quite often. This cost-cutting technique translates into long-term business savings, allows firms to put money in more appropriate areas, and enables them to increase the profitability. Looking at that, putting aside a certain amount of money for maintaining the seals of a particular quality that matches their needs can help companies to reduce costs and to prolong the lifetime of their equipment.

Factors to Consider When Choosing Custom Rubber Gaskets

Operating Conditions

Remember that the gasket’s conditions include temperature, pressure, and chemical exposure- select the best materials and affix the proper design. While in the conditions with maximum levels of heat, chemicals, and corrosion choose materials with the highest ratio of resistance in limit of heat, chemicals, and corrosion to ensure lasting reliability and performance.

Material Compatibility

Aim to implement the gasket material that is recommended for the nature of liquids or gases to be sealed because any degradation or contamination can affect the overall system. In applications where the contact with aggressive chemicals and solvents is probably preferred are the materials which are chemically resistant and allow to keep the seal consistent and prevent leaks or breakdowns.

Environmental Regulations

Abide by industrial rules about materials of gaskets and emissions to guarantee the fact of compliance and safety. In the field of environmental policies, it is necessary to make materials and designs which reduce environmental effects as much as possible and ensure compliancy with regulatory standards.

Case Studies of Successful Implementation

Think about real-life different examples, where topper custom rubber gaskets have transformed the performance and the reliability of many industrial equipment.

From automotive manufacturing as well as aircraft manufacturing Engineering, the examples given in this section show how gaskets are designed and used at different times, and the value they bring to the practice.

Future Trends in Custom Rubber Gaskets

Ensure that you keep tabs with newer breakthroughs in material science and design variants of manufacturing processes (i.e., maturing industrial 4.0 technologies) that may open the doors to novel innovations in custom rubber gasket technology. From developing new materials to applying advanced manufacturing methods like 3D printing, the ensuing generation of custom gaskets can yield interesting examples of how performance and reliability can be significantly improved.

Conclusion

Customized rubber gaskets play a significant part of every equipment efficiency and reliability to be achieved in the industry. These seals deliver a high seal reliability, as well as they absorb vibrations and withstanding extreme conditions which keep the high-quality operations and safety. Providing users with many personalization tools as well as a wide range of applications makes custom rubber gaskets a flexible tool that can be used for various industrial needs.

FAQs about Custom Rubber Gaskets

- What are the key benefits of using custom rubber gaskets in industrial applications?

- How do I choose the right material for my custom rubber gaskets?

- Can custom rubber gaskets withstand extreme temperatures and environmental conditions?

- What industries commonly use custom rubber gaskets, and why?

- Are there specific regulations or standards that govern the use of custom rubber gaskets in certain industries?