- CategorySponge Products

- Rating

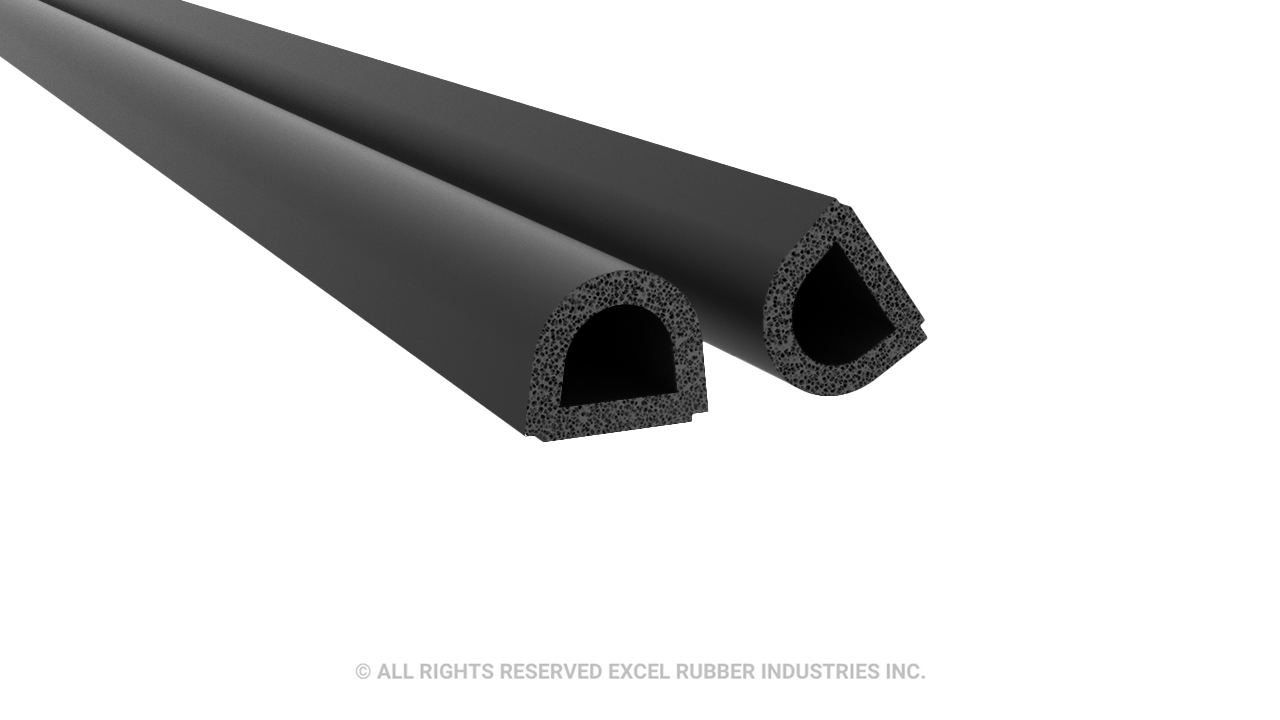

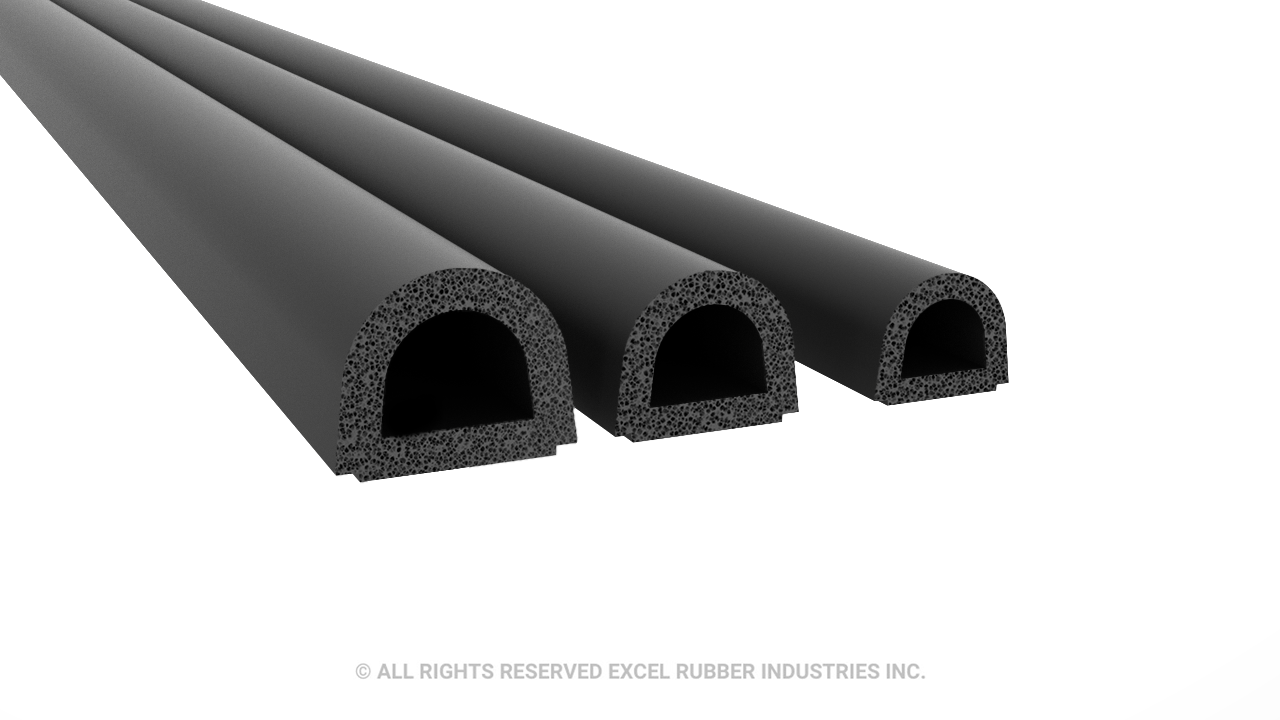

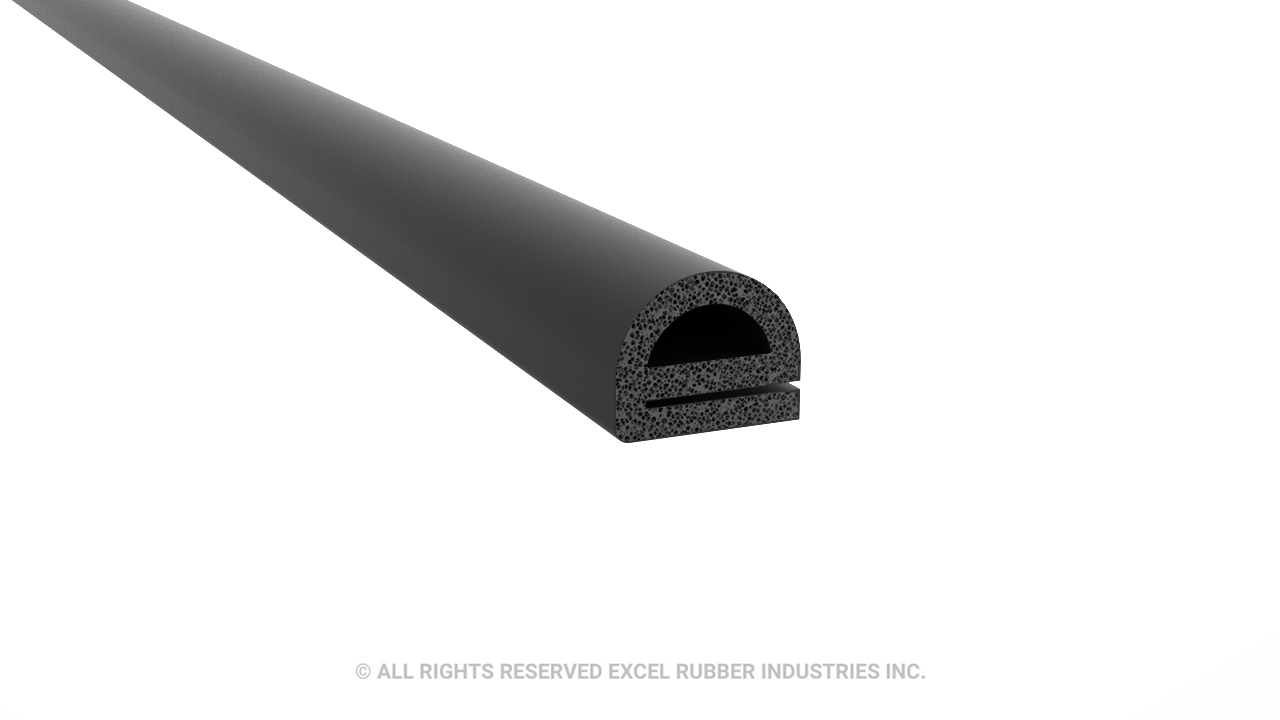

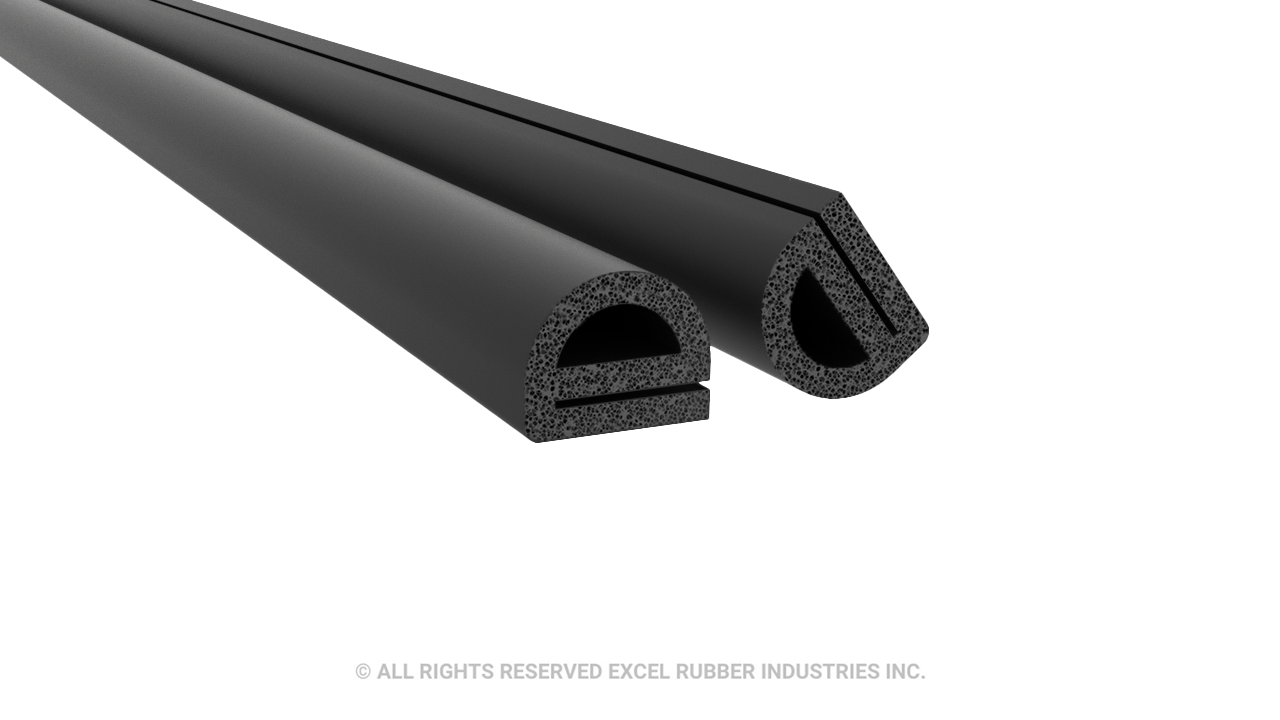

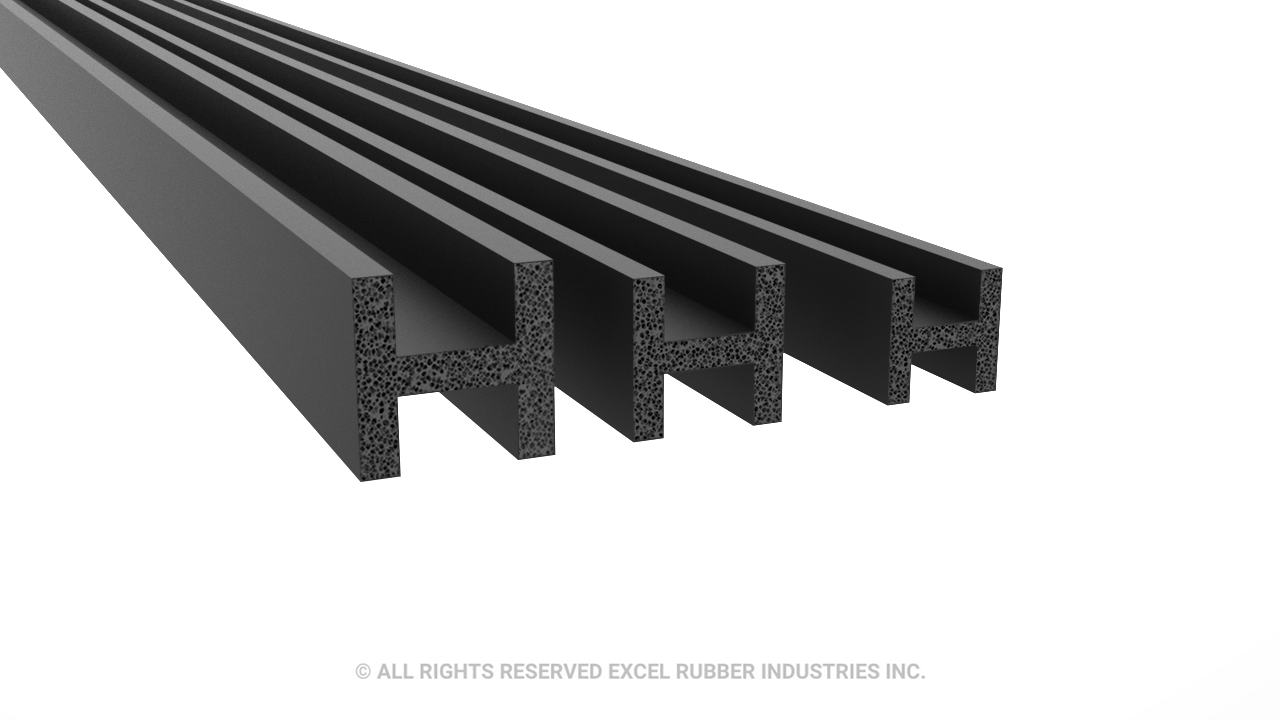

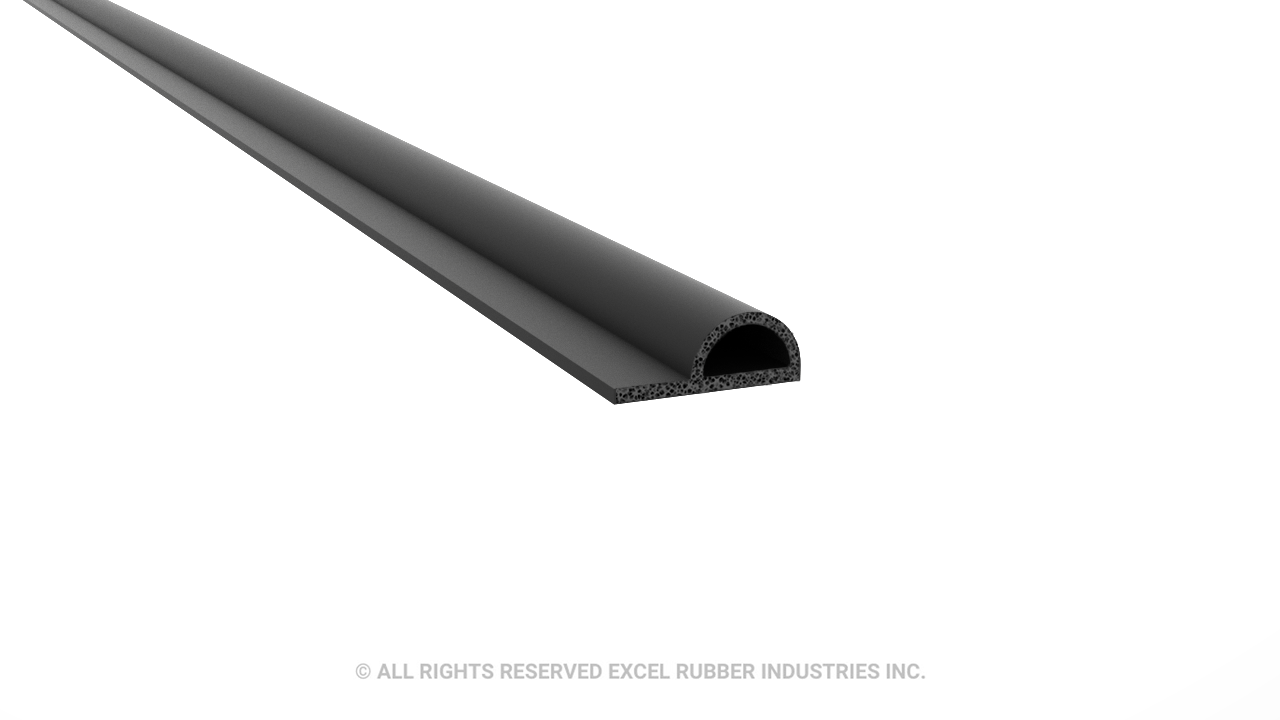

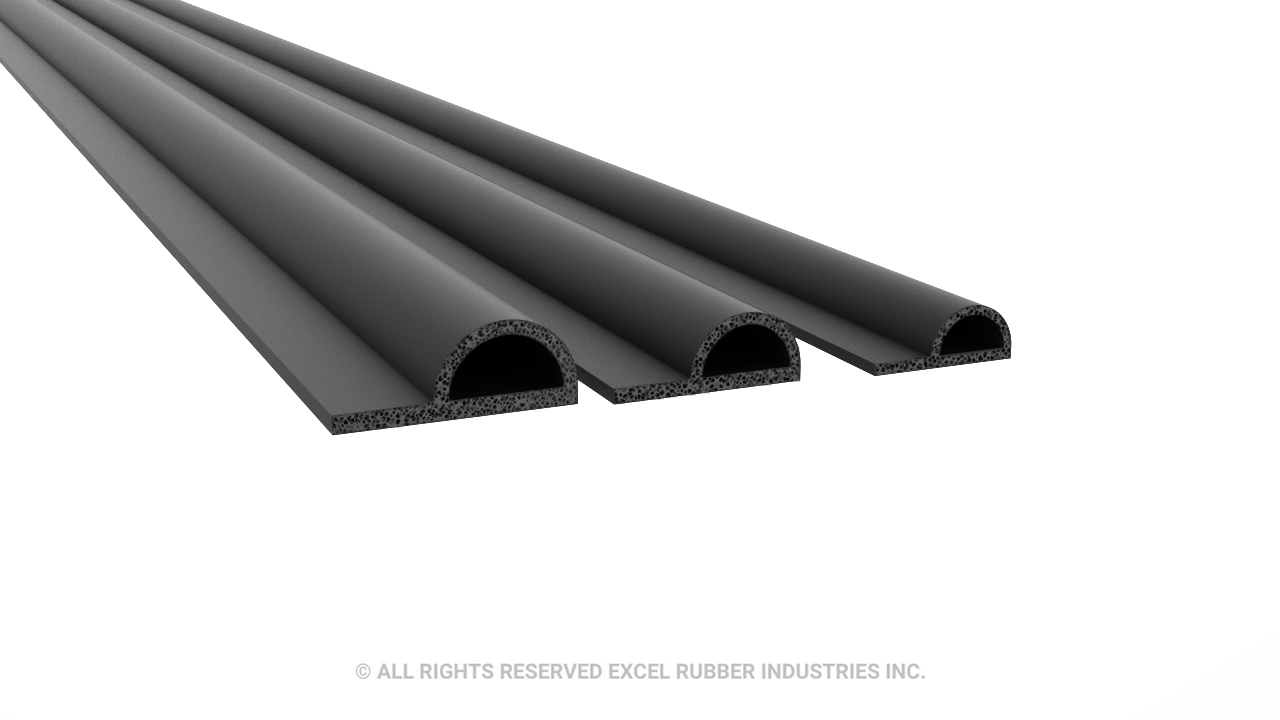

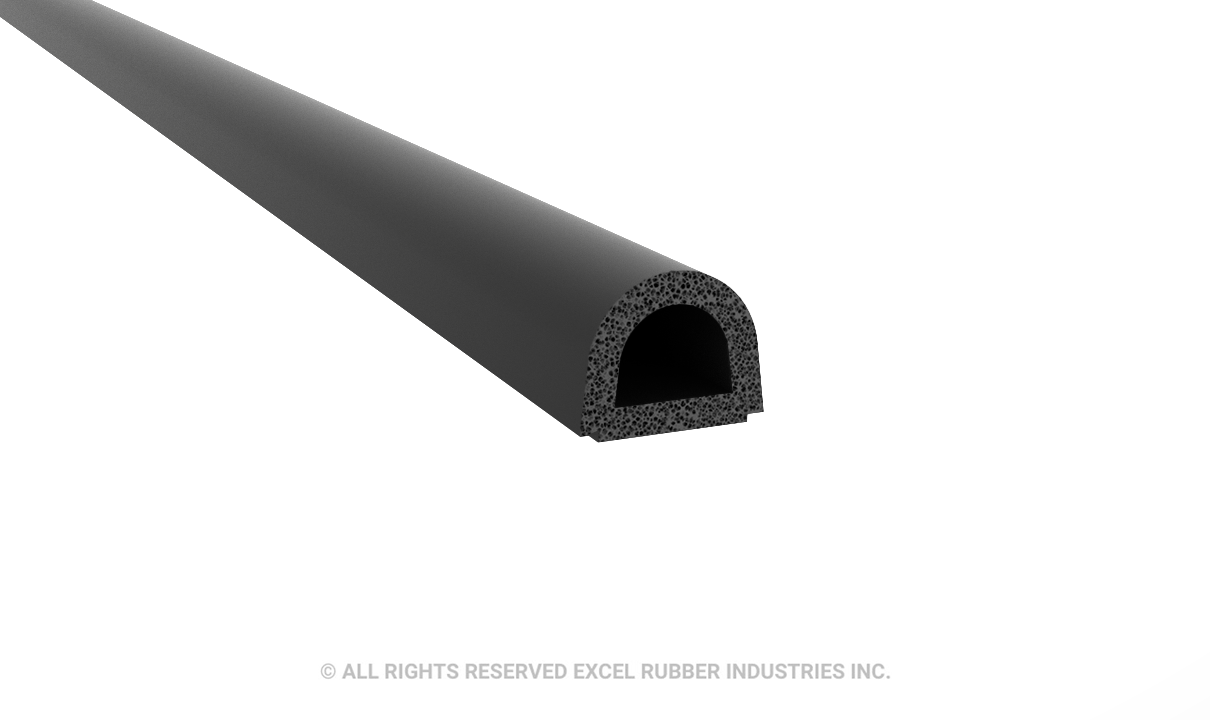

EPDM Sponge Seal

Product Description

Excel Rubber Industries Inc. makes sponge seals of very high quality and they come in many forms depending on the sealing needs. This rubber which forms our sponge seals is high grade closed cell EPDM foam that has good UV, good ozone and good oxidation resistance acid. These are fully and hermetically sealed to obtain technical properties of drain proof and weatherproof capable for use internally and externally.

Apart from the high-quality sponge seals, Excel Rubber Industries Inc. delivers EPDM sponge strips that are appropriate for a wide range of sealing purposes. These EPDM sponge strips offer good weather resistance that is suitable for indoor and outdoor purposes. With excellent sealing features, the EPDM strips offer dust, moisture, and variation coming from temperature extremes to prevent offering prolonged and dependable performance in industrial applications. To this regard, for those in need of a sealing solution that is flexible, hard wearing and easy to install, our selection of EPDM sponge strips should suffice for your sealing requirements.

Silicone and EPDM Sponge Seal Key Features:

- High-Quality Sponge Seals: These include the best usage and incorporation of the flexible and durable materials.

- Weatherproof Sponge Seals: Examination of the properties of this metal shows that it is very strong when it comes to withstanding the harshness of the weather and other conditions that may require a substance to be resistance to excessive wearing by rubbing or other friction. . .

Features:-

- A: HDPE Pipe Line is least exposed to weathering and abrasion.

- -B: HDPE Pipe Line has pleasant internal and surface external textures.

- -C: HDPE Pipe Line has a longer life expectancy.

- Airtight and Watertight Seals: This characteristic entails that the gasket will ensure no form of air crosses the barrier it covers.

- Wide Temperature Range: The performance temperature range of this device lies between -40 degree Celsius to 52 degree Celsius.

- Flexible Sponge Seals: They provide higher and improved compression ratio rates and flexibility.

- Custom Sponge Seals: regarding the foam it is available in different dimensions, density and statures and it exist in three forms which are the Soft, Medium and Hard.

Sponge Seal Applications:

- Automotive Sponge Seals: As to the car use of this sort of system buck refer to section 5.

- Marine Sponge Seals: Its purpose was to address certain situations on the water and be useful to those living near the water bodies.

- Glass & Glazing Sponge Seals: This is especially due to the superior qualities possessed making it especially suitable for application in glass and glazing .

- Ventilation Duct System: Window and this should be followed by the proper construction of walls and sealing of the windows.

- Lighting System: When applied to the power of lighting it was used the LEDs for lighting which comes under the category of MCM type used for lighting.

- Entertainment and Film Sets: In general appropriate for constructing the practising sets and generally for other set constructions.

Silicone and EPDM Sponge Seal Material Density:

- Soft Density Sponge Seals

- Medium Density Sponge Seals

- Hard Density Sponge Seals

Why Choose Excel Rubber for EPDM Sponge Seals

- Superior Material Selection: The EPDM sponge seals we import from italy are made from rubber material and they can easily withstand so many years of usage, stress from ozone and ultraviloate lights.

- Innovative Manufacturing Techniques: Different production styles are used in order to ensure that reliable quality is obtained when producing them.

- Reliability and Longevity: Many seals utilized for the high performance parts of the vehicle are made of EPDM sponge seal.

Kindly ask for expanded details of size of your cross section diameter and any other extra information you may need to add.