Introduction to Rubber Seals

Rubber sealing components are of core importance in every field to achieve the essential function of non-leaks, equipment protection and the highest possible performance. These seals are basically protective barriers, hence, they prevent the functionality of systems being impaired by the fluids, gasses, and contaminants. This detailed article will shed light on the scope of rubber seals, ranging from L seals, to J seals, H seals, ending with D seals. A thorough discussion of their parameters, features, areas of application, method of manufacturing, advantages and many other points will be made.

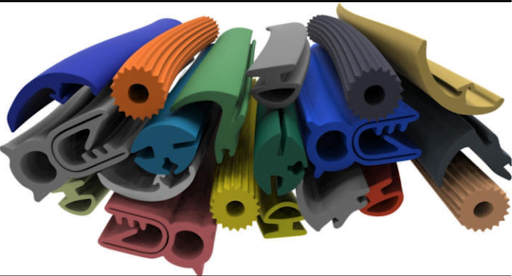

Explore Excel Rubber's Complete Range of Rubber Seals.

Understanding L Seals

One example of these sealing solutions is the L seals, also known as lip seals, that are tailored to meet specific needs of fairly any industry. Strength, adaptability, and sealing qualities of shoes have made them a symbol for the brand. C seals act as the cornerstone in preserving product integrity by providing a tight seal that does not allow leakage and thus ensures efficiency and productivity. They can fit these shapes and sizes of any size, which is why they are called upon to provide an effective seal in auto, air, and other industrial sectors.

Features and Benefits of L Seals

Due to the elastic property of L seals they are able to fit irregular surfaces tightly and, therefore, to increase the reliability of sealing. Moreover, they display great durability and hence they are able to withstand internal pressure differential and adverse environmental conditions without having any doubts on whether they can do their job alone. The advantages of L seals include equipment protection, reduced maintenance costs because of minimized leaks and the positive effects on system performance and increased system reliability.

This technology is being offered on an online store with necessary information, marketing strategy to set up as an independent standalone business with limited grounded staff.

Applications of L Seals

L seals can be applied to different fields such as manufacturing systems, compartment doors, and Air conditioners. Sealing of vehicle doors frequently by them is one of the practices which keeps water from coming in, dust from getting on inside and the noise from outside. The L seals have the same function of being an important point since they seal the ducts and joints and therefore, improve energy efficiency and indoor air quality. Moreover, practically they recover the majority of the contaminants from equipment enclosures and thus this results in smooth operation and prolonged equipment lifespan.

Ready to Improve Sealing Efficiency?

Exploring J Seals

J seals, these U-shaped, letter “J”-like closures incorporated into hydraulic and pneumatic systems, are vital parts in fluid containment. They are purposefully organized for high pressure sealing purposes. Besides these, they are recommended to reduce fluids, chemicals, and high temperatures leakages or corrosions. The manufacturing of different types of J seals is the core business activity of the company, which also allows making customized profiles and using the required material for specific application. The main applications of these seals are the hydraulic cylinders, pump assemblies, valves, and other equipment ending in considered trusted fluid or gas sealing techniques.

Different Variants of J Seals

The versatility of J seals lies in their ability to adapt to diverse operating conditions and performance demands. Excel Rubber’s range of J seals encompasses different profiles, materials, and sizes, ensuring compatibility with various hydraulic and pneumatic systems. Engineered to withstand harsh environments, they provide a durable barrier against leaks, ensuring optimal system performance and reliability.

Uses of J Seals

J seals serve critical functions in hydraulic systems, preventing hydraulic fluid leakage, maintaining system efficiency, and prolonging equipment lifespan. In pump applications, they ensure a tight seal between moving components, optimizing pump performance. Additionally, J seals are well-suited for marine equipment, offering resistance to saltwater, UV exposure, and harsh marine conditions, enhancing equipment durability and longevity.

Optimize Your Hydraulic Systems with Excel Rubber's J Seals.

Excel Rubber: A Trusted Name in Rubber Seals Manufacturing

Our customer—Excel Rubber has earned a reputation as a reliable and solution oriented leader specializing in delivering the most fit sealing products. What is more, these products are meant for meeting the needs of various industries across the globe. Our company, Excel Rubber, in Michigan is a premier manufacturer of rubber products. We specialize in the creation of top-notch rubber products by using our innovations that focus on quality, precision, and customer satisfaction.

Looking for Reliable Rubber Seals?

Manufacturing Excellence in Michigan

Manufacturing plant, located in Michigan, which comprises up-to-date machinery and devices, and dedicated only to producing superior seals from rubber materials. Via its skills in processing, molding and manufacturing they create crimping solutions that are exceptional respecting all the OEM quality control and what the customers need. Whether its train wheels or roll-on roll-off ferries, the high performance level is what Excel Rubber company is working to guarantee for all their customers.

Customized Solutions for Every Industry

With knowledge that the sealing requirements differ from case to case, Excel Rubber offers custom-made EPDM rubber seals solutions that are used to enhance industrial safety in unique applications, environments, and criteria. Regardless of our specific mission or using advanced materials to ensure quality products as a key goal, Excel Rubber exceeds the requirements we set. We can manufacture high-performance seals for cars and airplanes for the industrial sector as well as marine seals to make the operation of equipment easier and prolong its lifetime plus other benefits.

Emphasis on Quality and Innovation

Quality and innovation are the intrinsic values for every step of the process of Excel Rubber, starting from the thorough quality control the finished seals undergo which guarantees the precise match of the performance and quality of the seals as they should work. Research and development of the company are crucial to stay at the cutting edge of technology in rubber manufacturing because with this only Excel Rubber successfully makes sealing solutions by applying new-generation technologies to different parts of products.

Comprehensive Product Range

Excel Rubber has to offer different sets of seals, including L seals, J seals, H seals, D seals and many more through its broad rubber range to cover up an extensive variety of sealing predominantly for industrial applications. The company that has been working together with rubber extrusion dealers is able to offer its clients with assurance that they get reliable sealing for the job that needs them. This makes Excel Rubber a house to visit to buy rubber for any applications.

Conclusion

L seals and J seals, along with other critical seals, preserve sealing functions, permit leak-free functioning, reduce contamination risks, and improve equipment uptime for performance in high pressure sealing applications. High quality sealing is the core business of Excel Rubber, therefore its dedication to building superior solutions, facilitating innovation and providing the best service to clients makes it a trustworthy supplier of choice. Seals for high-pressure hung with H grading or D seals for weatherproofing can be configured based on specific application necessities, available backed with skilled expertise, reliability, and exceptional service.

H Seals: Essential Components for High-Pressure Environments

The H seals, which are also referred to as square or rectangular seals, are designed for a high-performance environment, and thus they can be found in many hydraulic and pneumatic systems. These seals get an exceptional sealing capability, hardness, and better resistance to very high temperatures and extreme chemicals utilizing renders them very proper for the demanding applications in concrete that of aerospace, defense, industry, and automotive.

Industries Benefiting from H Seals

Excel Rubber Company’s rubber seals are used industrially where they have proven to be robust and effective high pressure applications. Being superior rubber accouterment supplier in Michigan, Excel Rubber fulfills various needs of the things like spacecrafts, guards, manufacturing and transportation. These fields such as oil and gas industries use the quality sealing solutions provided by Excel Rubber to work efficiently and control the integrity of those systems.

Ready to Seal High-Pressure Environments?

Advantages of H Seals

Among the advantages the H seals of Excel Rubber have to offer are the sealing performance at high pressure, resistance of the heat, and chemical inertness. The rubber manufacturing operations in Michigan guarantees that A in Michigan consistently adhere to high quality parameters to surpass clients’ expectations in this competitive industry. We work with rubber extrusion companies and rubber extrusion manufacturers to ensure our standard H seals along with custom H seals are fit to customers’ particular needs.

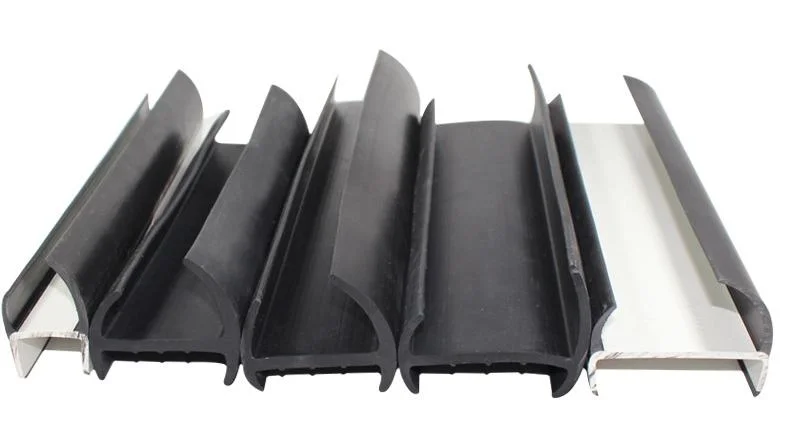

Understanding D Seals and Bulb Seals

D seals being other names for bulb seals or weatherstripping seals are extruded rubber products with multi-purpose and are commonly positioned on the doorways, windows, and machinery to restrict air, water and dust passage. These types of seals are through their shapes that become bulbous when clung offer a fantastic seal resistance, weather resistance, and strength.

Key Features of D Seals

Unlike many rubber industrial companies which produce high temperature rubber and rubber mats, Excel Rubbers extruded profiles range in D seals which all have different types of bulbs and profiles to ensure that the sealing performance is top notch. Collaborating with the e-seal hosters from Michigan is one of the reasons that the company provides unique sealing solutions. The company’s materials’ industries’s rubber products are widely respected for their reliability and lasting power, attracting these customers to become a key supplier in the area.

Applications of D Seals

D seals from Excel Rubber are used in gas, oil, as well as other industrial sectors, i.e. airspace, engineering, manufacturing, marine, and construction. The drastic environment changes found in space led to the increase in demand for rubber sealing profiles and products from Excel Rubber in Michigan. From the cabin pressure regulation to leaks prevention, these seals are stringent (and sometimes «heavy) in aerospace applications. Automobile manufacturers utilize Excel Rubber to manufacture window and door sealings that subsequently, greatly boost the performance and comfort inside their vehicles.

Explore Excel Rubber's D Seals for Effective Seal Resistance.

Advantages of Rubber Seals from Excel Rubber

While being a recognized provider of reliable sealing products through manufacturing custom and standard rubber products, Excel Rubber serves the whole list of industries globally. From expertise in Michigan in rubber manufacturing solutions to the exactness, uniformity and dependability in seal manufacturing by Excel, Rubber, we are prepared to meet the industry’s diverse demands.

Customized Solutions

Excel Rubber is known for its ability to manufacture customized rubber seals geared towards different clients, including L seals, J seals, H seals, D seals, and so on. It is their quality that has made them so successful. The team of experts at Excel Rubber works closely with mold manufacturers to supply the client with the best rubber e-sweat seal solutions available in the market.

Quality Manufacturing Processes

The manifest demonstration of commitment to quality is embodied in Excel Rubber manufacturing processes, which put the no compromise criteria in the first place ensuring high quality seals. Our processes from material choice and formulation to mold curing and testing have kept up to high technology to achieve products that meet industry standards and government regulations.

Diverse Product Range

In addition to Excel Rubber’s wide variety of rubber seals, our serving options include rubber ‘L’ seal profiles, ‘J’ seals, ‘H’ seals, ‘D’ seals and others that are used for sealing functions in varied industries. Their wide array of goods, and as well as their cooperation with the rubber extrusion manufacturers, ensure the customers of the quality jointing solution they are looking for.

Commitment to Customer Satisfaction

The highest achievement in terms of the Excel Rubber Company’s principle is the customer satisfaction achieved for the production of high quality products, on-time deliveries and customized solutions. Quality, reliability, as well as innovation are essential to this business, and these elements are what make them the preferred source of ašan industry that needs to implement high-in performance sealing. The quality, which manufactures products and sealing solutions meet the customers’ requirements as it ensures that it leads the rubber industry.

Conclusion

In conclusion, rubber seals are crucial components in sealing applications, ensuring leak-free performance, equipment protection, and operational efficiency. Excel Rubber’s commitment to quality, innovation, and customer satisfaction makes it a trusted provider of high-quality sealing solutions. Whether it’s H seals for high-pressure applications or D seals for effective weatherproofing, Excel Rubber delivers customized solutions backed by expertise, reliability, and unmatched service. As industries continue to evolve, Excel Rubber remains at the forefront of rubber manufacturing in Michigan, offering cutting-edge rubber solutions that meet the diverse needs of customers worldwide.