Introduction

In the machine world where the machines and the equipment are dizzying, stability and performance are the gloves of success. Be it the complex industrial machinery or the delicate electronic equipment, vibrations can be very destructive, by causing damages, reducing the efficiency, and at the same time, even creating safety risks.

This is where rubber vibration mounts earn their place as the unsung heroes, giving a simple yet effective solution to the vibratory problem and thereby ensuring the normal performance of the equipment.

In this thorough guide, we will go through the world of rubber vibration mounts, which will be discussed in detail with respect to their types, applications and the main function they perform is to increase the stability of the equipment and thus, the performance.

Table of Contents

Importance of Equipment Stability

Stability is the key component for machines and equipment in many industries. Without it, the level of productivity is likely to drop, the cost of the maintenance is likely to increase and the safety hazards are likely to materialize. The instability of the equipment may cause the misalignment, the lack of precise work and in extreme cases, can be a catastrophic failure.

Effects of Vibrations on Equipment

Vibrations are the causes of various damages on machines and equipment, for example, the wear and tear of the equipment, misalignment, and decreased precision are the results. On the other hand, in operations like precision machining, small vibrations can lead to the production of defective products or the scrapping of materials which in turn can lead to huge financial losses.

Understanding Rubber Vibration Mounts

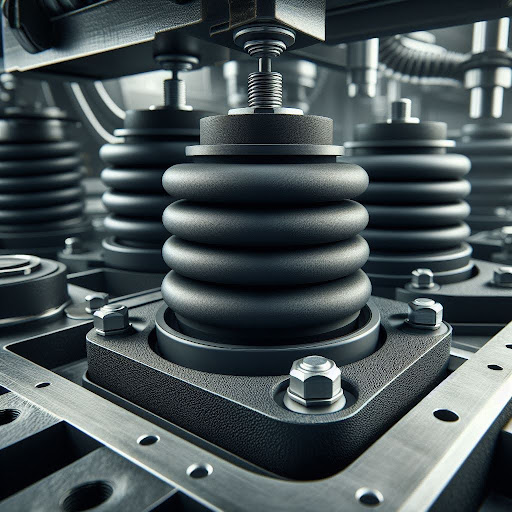

The rubber vibration mounts, which are also referred to as vibration dampening mounts, rubber isolation mounts, or anti-vibration mounts, are the components that are designed in a special way to absorb and isolate the vibrations that are generated by the machinery and the equipment.

These mounts are usually made of the best materials such as natural rubber, neoprene, or silicone which are the ones that have the best vibration damping properties. Rubber vibration mounts are such that they cut the center out of the equipment, thus, the vibrations are not being transmitted and thus, the noise is reduced, the wear and tear are minimized and the overall performance is improved.

Working Principle of Rubber Vibration Mounts

Vibration mounts made of rubber work by absorbing and dissipating the vibrations produced by the equipment and machinery. These mounts are usually made by elastic materials which have good vibration damping properties like natural rubber, neoprene, or silicone. Through the separation of the equipment from its environment, rubber vibration mounts impede the transmission of vibrations, thus, they will reduce the noise, eliminate the wear and tear and improve the whole performance.

Types of Rubber Vibration Mounts

There are different kinds and layouts of rubber vibration mounts, and each one of them is designed to suit certain applications and the performance requirements. Here are some commonly used types:Here are some commonly used types:

Rubber Shock Mounts

Rubber shock mounts, also called engine vibration mounts, are the equipment designed to absorb sudden shocks and vibrations, hence, they are crucial for the protection of the sensitive equipment and components. These mounts are often used in the automotive industry, thus, they are widely in the use of vibrations which are generated by the engines, transmissions, and other moving parts.

Rubber Machinery Mounts

Rubber machinery mounts are the heavy-duty mounts that are built to make the machinery and equipment stable and to support the large industrial machinery and equipment. These mounts are able to stand loads and at the same time they provide good vibration isolation characteristics. Thus they ensure the machinery to work smoothly and the lifespan of the machinery is increased.

Vibration Isolation Mounts

Vibration isolation mounts are the mounts, which are widely used to isolate the equipment from the vibration and shock, in different industries. They are in different forms and dimensions, including cylindrical mounts, bushings and sandwich mounts, that makes it easy to install in different applications.

Rubber Grommet Mounts

The rubber grommet mounts, also called rubber grommets or isolators, are the small, elastic mounts that are intended to isolate the vibrations and to give the cushioning in the different applications. They are mostly used to restrain and absorb the vibrations in electrical panels, the cabinets, and the HVAC systems.

Applications of Rubber Vibration Mounts

The rubber vibration mounts are used in many industries and sectors where vibration control is the key to the high performance and long life of the equipment. Some common applications include:

Industrial Machinery

In the machining facilities, rubber vibration mounts are employed to separate the heavy machines such as presses, mills, and lathes, hence, in the process, the vibrations are controlled and the structural damage is prevented.

HVAC Systems

In the heating, ventilation, and air conditioning (HVAC) systems, vibration mounts are used to reduce the noise and vibration transmission from the compressors, fans, and motors which are the sources of noise thus, ensuring the smooth and quiet functioning of the system.

Transportation

In the automotive, aerospace, and marine industries, rubber vibration mounts are of great importance in dampening the vibrations from engines, transmissions, and propulsion systems that are, thus, enhancing the ride comfort and reducing component fatigue.

Electronics and Appliances

In the field of consumer electronics and appliances, such as washing machines, refrigerators, and computers, rubber vibration mounts are applied to provide a stable base, lessen the noise and to prevent damage from vibrations that come as a result of operation.

Benefits of Rubber Vibration Mounts

The utilization of rubber vibration mounts offers numerous benefits, making them indispensable in various applications:The utilization of rubber vibration mounts offers numerous benefits, making them indispensable in various applications:

Vibration Dampening

Rubber vibration mounts are the best tools to reduce vibrations and hence, noise. They also prevent the vibrations from getting transferred to the nearby structures and components.

Equipment Protection

Through the isolation of machinery and equipment from vibrations, rubber mounts hinder the contact of the sensitive parts with the vibrations, thus, they protect the components from the damage, and as a result, they prolong their life and reduce the maintenance costs.

Improved Performance

Decreased vibrations mean that the machinery and equipment run more smoothly and therefore, the performance of the company increases and the productivity and efficiency are high.

Safety Enhancement

Rubber vibration mounts are used in applications where excessive vibrations are a safety hazard like in construction machinery or aerospace systems. These mounts are useful for enhancing safety because they stabilize the equipment and there is a reduced chance of accidents.

Versatility

Rubber vibration mounts are now made in different shapes, sizes and load capacities, thus, they can be used for a variety of applications across different industries.

Selection and Installation Considerations

While choosing the rubber vibration mounts for a particular application, several factors have to be considered which among them are the load capacity, the environmental conditions and the mounting orientation. Moreover, the right installation is the most important thing to guarantee the best performance and the life of the mounts. Here are some key considerations:Here are some key considerations:

Load Capacity

Choose mounts that have the necessary load capacity to carry the weight of the equipment and to stand the shock loads during use.

Environmental Conditions

Think about the operating environment, which is composed of temperature extremes, the presence of chemicals, and the possible contamination sources, and choose the mounts that are suitable for these conditions.

Mounting Orientation

Make the mounts of the right alignment and orientation so that they can be maximum effective in the isolation of the vibrations. Adherence to manufacturer guidelines for the installation procedures and the hardware for mounting is imperative.

Maintenance

It is crucial to conduct the rubber vibration mounts regularly and check their condition in order to find the signs of wear and damage and thus prevent the premature failure. Swap out the degraded or broken mounts now to prevent the deterioration of equipment performance and safety.

Maintenance and Troubleshooting Tips

It is crucial to carry out regular checks and maintenance of rubber vibration mounts to ascertain wear or damage and thus to avoid the premature failure of the product. The inspection process should be comprised of check of cracks, tears, or deformation of rubber material, also, the tighter and more proper the alignment and mounting hardware are, the better. Besides, the identification of the common issues such as too much vibration or noise can help to find the real problem and to deal with it in time all together.

Future Trends and Innovations

New trends and inventions in vibration control technology, for instance, the development of new materials, intelligent sensors, and the predictive maintenance techniques, are the driving force of the future of the equipment stability and performance. As an example, the incorporation of smart sensors and real-time monitoring systems makes it possible for the operators to be proactive in the maintenance, which will help them to spot problems early on and thus, they will be able to avoid a situation where they will have to spend more money dealing with the damages that will be caused in the future. Also, the improvements in the materials science are the major factors that are making the rubber vibration mounts more effective and durable in difficult operating conditions.

Environmental and Sustainability Considerations

The environmental impact of rubber vibration mounts should be the issue of priority in order to promote sustainable manufacturing. Manufacturers are nowadays paying attention to using eco-friendly materials, the realization of recycling initiatives, and the reduction of energy consumption in the production of rubber mounts. Besides, the creation of designs for the durability and recyclability of the mounts can reduce waste and environmental impact during the entire life of the product.

Conclusion

Rubber vibration mounts are the main factors that boost the stability and the performance of equipment in the different industries. From the industrial machinery to the consumer electronics, these versatile components provide vibration isolation, noise reduction, and equipment protection which are the main reasons for their ability to guarantee the smooth operation of the equipment and its long life.

Through the study of the different types, applications, and benefits of rubber vibration mounts, engineers and designers can make the right decisions to enhance the equipment performance and provide a safer and less noisy working environment.

Rubber vibration mounts are, without any doubt, the best helpers in the search of stability and performance anyway, be it the reduction of vibrations in a manufacturing plant or the improvement of ride comfort in a vehicle.