Rubber is the ultimate recyclable material which is acclaimed and deeply appreciated for its unmatched ductility, capacity to withstand a great number of conditions, and immense destruction of the environment. EPDM, Neoprene, and Nitrile are a distinct group of rubbers within the rubber diversity and characteristically are differentiated by properties and usages. This all-encompassing manual aims to introduce you to the broad features, merits and purposes that EPDM, Neoprene, and Nitrile rubber have to offer, so that you get to make that very important decision on what you exactly want.

Introduction

Rubbers indisputably occupy the limelight in many industries on account of their innate bounciness and ability to acclimatize to specific climate conditions. The group of the EPDM (Ethylene Propylene Diene Monomer), Neoprene (Chloroprene), and Nitrile (NBR) is called top-three popular rubbers with their own specific beneficial effects and properties appropriate to the various industrial applications.

Understanding EPDM Rubber: Endurance Redefined

Not only EPDM rubber is credited for its unmatched thermal performance and lifetime efficiency but also for its outstanding weather resistance. It is not up to the challenge of fighting for a long time in the presence of ozone, UV rays, and the high temperatures. Having a beat on these implies the usage of the EPDM roofing on outdoor applications more than any other choice. It is by sustaining the hearty property of the down that this material will be freeze proof in sub-zero temperatures leading to tenacious longevity of performance and utility throughout the various environmental situations.

Properties of EPDM Rubber

EPDM Rubber is salted with unusual resilience to moisture, chemicals and abrasion which helps it in making robust sealing joints, backing sheets for roofing appliances, and in automobile components development. Meanwhile, the coupled effect of exceptional tensile strength and dynamic ductility in performance enhances I.e. high temperature resistance and suitability for high passing load make EPDM material the best choice for many, if not most of the demanding industries.

Advantages of EPDM Rubber

By nature, EPDM rubber is superior to sunlight, ozone, and heat exposure, and this turns the material into the best recommendation for outdoor and automotive settings. The superiority of this material regarding wearability, resilience, and being barely maintained has enhanced its acceptance in the construction and manufacturing industries with the benefit of having a life span which can’t be undermined.

Through the use of strategically placed and relevant keywords, as well as well-informed information, we strive to provide detailed and informative information to expand your understanding of the properties, advantages, and uses of EPDM rubber.

EPDM rubber’s unique properties translate into several advantages that position it as a preferred material choice in numerous applications:EPDM rubber’s unique properties translate into several advantages that position it as a preferred material choice in numerous applications:

Risk of Corrosion, Ozone, and High Temperature Challenges

This variety of EPDM material possesses an exceptional ability to endure weathering, ozone attack, and heat up to higher levels. Therefore, it is appropriate for the outdoor and automotive industries. The EPDM rubber will still be in good condition even if it is facing extreme cold or hot temperatures or with harsh UV rays. The EPDM rubber still performs well in the environment that is tough to take on.

Durability and Flexibility

The core set of features, which make EPDM rubber such a favorite in the construction industry and in manufacturing, are its remarkable durability and ability to adapt to various conditions. It maintains the console’s durability under extreme conditions by implementing both hardness and flexibility thereby increasing productivity while keeping repeating maintenance costs away.

Low Maintenance Requirements

The cost-saving, low maintenance nature of the product is an additional benefit that people with different interests can appraise it. Contrary to other materials that may be replaced quite often, EPDM rubber seals and components run hassle-free and achieve a reliable and trouble-free operation, hence less downtime and lower costs.

EPDM Rubber Properties: Comprehensive Insights

The rubber EPDM is the proof that durability is truly real. The rubber can even resist almost any atmospheric manifestation. Its amazing properties makes it one of the perfect solutions that best suits for a variety of uses in the different types of industries. Let’s explore the distinct characteristics that make EPDM rubber a preferred choice:

Let’s explore the distinct characteristics that make EPDM rubber a preferred choice:

As far as resistance to moisture, chemically and abrasion goes, this fabric is top-notch.

EPDM is the best choice among others because of its unique feature in such a way the excellent resistance to the environment (moisture, chemicals, and abrasion). Irrespective of whether the EPDM rubber material is exposed to corrosive chemicals or intense abrasions, it still executes its tasks with almost no changes in characteristics until its end of service life.

High Tension Strength and Elongation characteristics.

These two striking characteristics, which include the EPDM rubber’s high tensile strength and elongation, make this material a perfect asset for numerous applications. EPDM rubber sealants, roofing membranes and car components are just a few examples of its versatility. EPDM exhibits the needed strength and flexibility to satisfy various operating conditions and therefore guaranteeing maximum performance and long life span when used.

Versatility in Sealing Applications

EPDM rubber is suitable for various types of sealing tasks in coverage of cross industries. The unique capability of sealing the deformations that have sufficiently moisture and environmental resistance properties is the main advantage of this material for various applications for sealing. Looking up, whether in construction or automotive industries, EPDM rubber seals are used for providing resistance against rain and that too in a reliable way and for longer durability also.

Exploring EPDM Rubber Applications

EPDM rubber’s versatility extends to a myriad of applications across industries, where its unique properties deliver unparalleled performance and reliability:EPDM’s multifariousness is noticeable for use in a wealth of applications throughout the industries, where the characteristics of the material stand for excellence and stability.

Roofing Systems

EPDM rubber is indeed one of the most known roofing membranes and the main reason behind the using it is its wonderful ability to withstand weather with exceptional durability. The third most preferred building material, EPDM roof system, is also suitable for parapet lining, and just as used on sloping and flat roofs when the material is installed, it gives a guarantee of reliability against moisture and natural environmental elements. This leads to long term structural integration of the building.

Automotive Seals and Gaskets

The number one number automotive industry concern is our first-rate quality of automotive seals and gaskets.

In the automotive sector, EPDM will receive the largest area of application due to its seal and gasket applications on doors, windows and engine parts. By producing solid and tight seals the vehicle’s fuel pressure is increased, and overall performance + comfort enhanced. Daily usage and exposure to variable temperature changes will not make any difference to the seals.

Weather Stripping and Pond Liners

The weather stripping applications imply that this EPDM rubber is the most appropriate material since it excellently seals the gaps and stops air or water from penetrating. Besides, EPDM pond liners designed specifically for water features provide the leak-proof setting and make sure of their reliability for long-time operation.

Electrical Insulation

Its electrical resistance leads to uses as electrical insulation for instances such as cable insulation or wire harnesses. This is made possible by its ability to withstand electricity and environmental influences through its ruggedness, which will maintain its reliable operation and create safety in the electrical systems.

Through unravelling the various uses of EPDM rubber and the inherent technical advantages behind it, we in turn appreciate the far-reaching relevance of this commodity across many domains and industries.

How Do EPDM Rubber Products Benefit Your Projects?

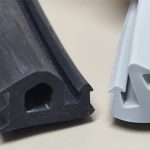

Although there are many kinds of EPDM rubber goods, such as H seals, D seals, L seals, J seals, Omega seals, sponge seals, sponge rubber lines, and sponge tubing, these products render a wide range of benefits in many industries and applications. These EPDM rubber components are designed and fabricated with the main purpose of providing optimum sealing effectiveness, resistance to damage from weather conditions and durability in arduous environments.

O-rings, EPDM H seals, D seals, L seals, J seals, and Omega seals are designed to be made from materials which are perfect for tight windows and door sealing and access hatch sealing against leaks. The tensile and adaptable characteristics that I value so much in my running shoes will never fit me treacherously in the harsh weather, and the UV rays exposure. These EPDM seals can help perform their functions better by tightly closing joints and gaps and hence boost energy efficiency, decrease noise transmission, and protect the interior from moisture or drafts.

In addition, EPDM foam seals provide the best resistances against compression and elasticity, thus they play the major role in cushioning and absorbing vibration. This rubber EPDM pad is quite multipurpose and it is applied in automotive weather sealing, HVAC systems, and industrial machine gaskets among other places where seals are crucial in order to provide reliable sealing and insulation properties and at the end of the day, contribute towards increased operation and durability of the equipment and its components.

EPDM sponge cords and sponge tubing fabrications are universal sealing, cushioning and protecting solutions for surface and material protection in various scenes. This soft and moldable property makes the materials shear secure on the surface of uneven areas and irregular shapes. End products varying from automotive gaskets to electrical enclosures now use EPDM sponge rubber cords and tubing for proper sealing against moisture, dust, and environmental contamination to obtain the expected operable and reliable qualities.

To summarize, EPDM rubber products possess many pros like undefeated sealing activity, immunity to and also tenderness, toughness and also adaptability. In the case of using for residential, commercial and industrial applications, such as EPDM seals, sponge seals, rubber cords and tubing, they are necessary in order to uphold efficiency, comfort and durability in the varying environment and industry.

- EPDM Rubber H Seal: Excellent for caulking of joints and sealing leverages around windows and doors.

- EPDM Rubber D Seal: Can be used for securing gates, hatches, and compartment doors.

- EPDM Rubber L Seal: Installation of a sealer on all the joint corners as well as edges of the board in the construction.

- EPDM Rubber J Seal: It has been created for sealing and waterproofing the edges and corners of the windows and glass.

- EPDM Omega Seal: Its high sealing performance is for windows, doors, and other thermal openings.

Comprehensive Insights into Neoprene Rubber

The detail here refers to Neoprene rubber, widely known as chloroprene-derived synthetic rubber, generally famous for its outstanding attributes as well as diversified utilization across various industries. Let’s explore in-depth the distinct characteristics, advantages, and applications of Neoprene rubber:

Let’s explore in-depth the distinct characteristics, advantages, and applications of Neoprene rubber:

Neoprene Rubber Properties

Neoprene rubber is very special for being proof against oil, chemicals, and flame (it does not burn). It is extremely useful for this type of working environment where there is a great diversity of tasks and products. Its characteristic to remain flexible at a wide range of temperatures as well as provide an excellent weather proofing for stability and durability of the device makes this device a perfect choice for use in various environments.

Resistance to Oil, Chemicals, and Heat

A prominent benefit of Neoprene is the fact that it is able to withstand oil, solvents, and high temperatures without being damaged, and for that reason it is widely used in industrial applications such as protecting cables or insulating electrical panels. This property makes it the most appropriate raw material for manufacturing applications in chemical industries, which needs exposure to high temperature and harsh chemicals in hoses, gaskets, and industrial seals.

Stability and Durability

Neoprene rubber shows a remarkable level of stability and resistance against the damage, which is deemed as especially good for marine applications and protective equipment. Its ability to withstand saltwater, sunlight and other factors of environment for long durations without compromising its structure puts it far ahead of other materials ind traceable in marine and outdoor settings.

Advantages of Neoprene Rubber

Neoprene rubber offers a multitude of advantages that further enhance its appeal across various industries.

Enhanced Longevity and Performance

Neoprene rubber is a chemical resistant, seal proof, and weather durable material that offer the benefits of extended lifecycle with consistent performance over time. Tire’s built-in elasticity and flexibility make the tire capable of holding its shape, having all the properties, even when it is subject to continuous stress. This makes the tire endure products of the best quality.

Versatility in Applications

The fact that Neoprene rubber is extremely versatile enables it to play a significant role in a multitude of fields from the automotive industry all the way to machinery production at factories. It is no exception since it can be used within automotive hoses, gaskets, wetsuits, gloves and so on. Also, it is utilized in industrial seals, conveyor belts, and hydraulic hoses implying its multifunctional value across different sectors.

With all these insights, it shows that the global market for nitrile rubber is growing at a steady rate which means there is a good business opportunity for all the competitors in the market.

Nitrile Rubber Insights

Nitrile rubber (NBR, or Nitrile Butadiene Rubber) is a synthetic rubber with excellent oil tolerance and strength. Its antimicrobial abilities keep it from being biodegraded by bacteria. Let’s explore the unique properties, advantages, and applications of Nitrile rubber in greater detail:Let’s explore the unique properties, advantages, and applications of Nitrile rubber in greater detail:

Nitrile Rubber Properties

Nitrile rubber stands apart from others thanks to its excellent resistance to oils, fuels, and chemicals. This feature makes it not only the first choice for products calling for contact with hydrocarbons and industrial fluids but also the number one selection in the industry. The durability of these objects is also high tensile strength and resistance to abrasion, making them the best option for demanding cases.

Superior Resistance and Durability

Nitrile is known for its ability not only to resist the temperature extremes, but also the oils ,fuels and chemicals without its properties decreasing. This feature is attributed to the application areas like seals, gaskets, and O-rings in automotive, aerospace, and industrial where the leak proofing requirement is stringent.

Exploring the Applications of Nitrile Rubber

Nitrile rubber finds extensive use in a wide range of applications across diverse industries:Nitrile rubber finds extensive use in a wide range of applications across diverse industries:

- Automotive Seals and Gaskets:

The Nitrile rubber is widely used as seals, gaskets, fuel hoses and O-rings in the first place because of its strong resistance to oil, eroding as well as resistance against wear and tear.

- Industrial Machinery:

Industrial firms nowadays manufacture different equipment and machinery from the use of the material as aids in hydraulic systems, conveyor belts, and other machineries where resistance against oils and chemicals is the main priority.

- Medical and Laboratory Equipment:

Nitrile rubber gloves are commonly seen in the medical field and laboratories because they are the best option to counteract oils, chemicals, and pathogens.

- Consumer Products:

Ranging from home items to sporting goods, Nitrile rubber appears in multiple products in different forms due to its involving attributes like durability and flexibility.

Comparison of Rubber Properties

| Properties | EPDM | Neoprene | Nitrile |

|---|---|---|---|

| Weather Resistance | High | Moderate | Low |

| Oil Resistance | Low | High | High |

| Temperature Range | -50°C to 150°C | -40°C to 120°C | -40°C to 120°C |

| Flexibility | Excellent | Good | Good |

| Chemical Resistance | Good | Good | Excellent |

Conclusion

Understanding the properties and applications of EPDM, Neoprene, and Nitrile rubber is essential for selecting the right material for your specific requirements. Whether you need weather-resistant roofing membranes, oil-resistant seals, or chemical-resistant hoses, each type of rubber offers unique benefits suited to diverse applications.

FAQs

1. Which rubber is best for outdoor applications?

EPDM rubber is best suited for outdoor applications due to its excellent weather resistance and durability.

2. Can Neoprene rubber withstand exposure to oils and chemicals?

Yes, Neoprene rubber offers good resistance to oils, solvents, and chemicals, making it suitable for various industrial applications.

3. What are the temperature limits for Nitrile rubber?

Nitrile rubber can withstand temperatures ranging from -40°C to 120°C, making it suitable for a wide range of environments.