Introduction:

Welcome to Excel Rubber’s comprehensive guide on the extraordinary versatility of EPDM rubber and its extensive applications across diverse industries. As a leading provider of rubber solutions in Michigan, Excel Rubber takes pride in delivering top-notch products tailored to our clients’ unique needs. In this article, we explore the various facets of EPDM rubber, from its molecular structure to its crucial role in the automotive, construction, consumer, and industrial sectors.

Table of Contents

Brief Introduction to EPDM Rubber:

Unveiling the Resilience of EPDM Rubber:

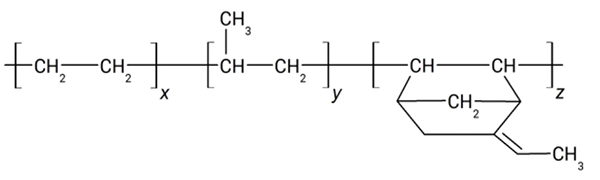

Excel Rubber introduces EPDM rubber, a synthetic elastomer renowned for its resilience, weather resistance, and multi-applicability. The molecular structure of EPDM, composed of ethylene and propylene units connected by dienes monomers, imparts unique properties, making it a versatile material for a wide range of industries.

Significance of EPDM Rubber in Different Industries:

EPDM rubber’s significance in various industries stems from its high resistance to environmental stressors like UV rays, ozone, extreme temperatures, and chemicals. Excel Rubber emphasizes its role in the automotive industry, where EPDM is widely used for seals, gaskets, hoses, and more.

Summary of the Main Topics in the Article:

This all-encompassing article provides a deep dive into the composition, distinctive traits, and vital contributions of EPDM rubber across different industries, particularly in the automotive sector. Each chapter investigates the nature, uses, and value of EPDM, showcasing its versatility and robustness.

Understanding EPDM Rubber:

What is EPDM Rubber?:

Molecular Magic of EPDM:

Excel Rubber unravels the molecular structure of EPDM, characterized by long chains of ethylene and propylene alternated by diene monomer units. This structure grants EPDM its elasticity, weather resistance, and durability, making it a universal material generated through copolymerization.

Properties and Composition:

- Durability and Weather Resistance:

EPDM’s outstanding durability and resistance to harsh climatic conditions make it a standout material. Excel Rubber’s EPDM excels against UV radiation, ozone exposure, and extreme temperatures, ensuring a long service life.

- Heat and Chemical Resistance:

EPDM’s resistance to heat and chemicals positions it for applications demanding stability and reliability in harsh environments. It remains robust in the face of acids, alkalis, oils, and other chemical agents.

- Flexibility and Insulation:

EPDM’s flexibility and remarkable electrical insulation properties enhance its suitability across manufacturing processes and electric and construction applications.

EPDM Rubber Applications in the Automotive Industry:

EPDM in Vehicle Seals and Gaskets:

EPDM rubber takes the spotlight in the automotive industry, serving as the primary material for seals and gaskets. Excel Rubber emphasizes EPDM’s sealing properties, weather resistance, and reliability, ensuring essential parts in vehicles, including rubber L seal profiles, rubber J seal profiles, and rubber D seal profiles, remain leak-free and perform optimally.

To learn more about our different rubber seals you can visit: Click Here

EPDM in Hoses and Tubing:

EPDM rubber’s strength, and resistance to high temperatures, chemicals, and aging make it a preferred choice for hoses and tubing systems in vehicles, incorporating rubber L seal profiles, rubber J seal profiles, and rubber D seal profiles. Excel Rubber’s EPDM hoses ensure fluid transport with longevity and efficiency.

EPDM in Automotive Roofing:

EPDM’s characteristics make it a popular choice for automotive roofing systems. Excel Rubber highlights its durability, weather resistance, and cost-effectiveness, protecting vehicles with incorporated EPDM sponge gaskets and EPDM sponge seals.

EPDM Rubber in Construction and Architecture:

Excel Rubber's EPDM in Roofing and Waterproofing:

Excel Rubber’s EPDM takes center stage in roofing systems, driven by unparalleled durability and weather-resistant characteristics. This synthetic rubber material showcases outstanding resilience against harsh weather conditions, UV radiation, and ozone exposure, making it an ideal choice for incorporating EPDM sponge gaskets and EPDM sponge seals in roofing applications.

Advantages in Roofing Systems:

Excel Rubber’s EPDM flexibility and adaptability are crucial advantages, especially in Michigan, where temperature fluctuations are common.

Waterproofing Capabilities:

In waterproofing applications, Excel Rubber’s EPDM serves as an efficient barrier against water ingress, offering robust protection against potential damage caused by leaks or seepage.

Excel Rubber's EPDM in Sealing and Insulation:

Excel Rubber’s EPDM’s significance in sealing applications is paramount for creating airtight seals in construction, preventing air or water infiltration, and enhancing energy efficiency within Michigan buildings.

Importance in Sealing Applications:

Excel Rubber’s EPDM’s ability to create durable seals significantly contributes to reducing heat loss and ensuring optimal insulation.

Insulation Benefits in Construction:

Beyond sealing, Excel Rubber’s EPDM’s thermal stability and insulating properties regulate temperatures within buildings, creating a comfortable environment while reducing reliance on heating or cooling mechanisms.

In essence, Excel Rubber’s EPDM is reshaping construction and architecture in Michigan by providing a reliable, cost-effective, and sustainable solution in roofing, waterproofing, sealing, and insulation. Its versatility, durability, and ability to enhance energy efficiency make Excel Rubber’s EPDM indispensable in modern building practices.

As Excel Rubber’s EPDM continues to be integrated into construction methodologies, its application versatility and eco-friendly attributes position it as a frontrunner in Michigan’s quest for more sustainable and efficient building materials. This widespread adoption underscores Excel Rubber’s EPDM pivotal role in shaping the future landscape of construction and architecture, aligning with global sustainability goals by promoting energy efficiency and reducing environmental impact.

In conclusion, Excel Rubber’s EPDM stands as a testament to innovation, reshaping the construction and architectural landscape in Michigan with its multifaceted advantages in roofing, waterproofing, sealing, and insulation. Utilizing Excel Rubber’s EPDM not only ensures the longevity and resilience of buildings but also aligns with global sustainability goals, making it a key player in Michigan’s construction revolution.

EPDM Rubber for Industrial and Manufacturing Purposes:

EPDM in Conveyor Belts:

Conveyor belts are indispensable in numerous industrial processes, and EPDM rubber plays a vital role in enhancing their performance and longevity. As a reliable supplier of EPDM solutions in Michigan, Excel Rubber understands the importance of abrasion resistance, heat stability, and chemical resilience in conveyor belt applications, including rubber L seal profiles, rubber J seal profiles, and rubber D seal profiles.

EPDM in Vibration Isolation:

Excel Rubber recognizes the significance of vibration isolation in machinery across Michigan’s diverse industries. Our EPDM rubber isolators effectively dampen vibrations, ensuring smoother operations and prolonged equipment lifespan.

EPDM in Electrical Insulation:

In the electrical industry, Excel Rubber’s EPDM solutions provide reliable insulation for cables and wires, incorporating rubber L seal profiles, rubber J seal profiles, and rubber D seal profiles. Our products, tailored for Michigan’s climate, resist moisture and maintain thermal stability, ensuring safety in electrical systems.

In conclusion, Excel Rubber stands as a key player in providing EPDM solutions tailored for Michigan’s industrial landscape. Our commitment to quality, durability, and versatility makes us the go-to supplier for EPDM rubber across industries in Michigan. As technology advances, Excel Rubber remains at the forefront, meeting the evolving needs of Michigan’s manufacturing sector.

EPDM Rubber in Consumer Products:

EPDM in Consumer Electronics:

In the fast-paced world of consumer electronics, where innovation and reliability are paramount, EPDM rubber emerges as a key player. Excel Rubber’s EPDM solutions cater to the intricate needs of the electronics industry in Michigan, providing durable components that withstand the rigors of daily use, including rubber L seal profiles, rubber J seal profiles, and rubber D seal profiles.

EPDM in Sporting Goods:

Sporting goods demand materials that can endure the elements, providing durability and performance. Excel Rubber’s EPDM solutions are tailored to meet the specific requirements of sporting goods manufacturers in Michigan, contributing to the resilience and longevity of various products, including rubber L seal profiles, rubber J seal profiles, and rubber D seal profiles.

EPDM in Household Products:

EPDM rubber plays a vital role in enhancing the performance and longevity of everyday household products, including rubber L seal profiles, rubber J seal profiles, and rubber D seal profiles. From seals in appliances to grips on tools, Excel Rubber’s EPDM solutions contribute to the durability and functionality of household items in Michigan.

Environmental Impact and Sustainability of EPDM Rubber:

Recyclability and Eco-Friendliness:

Excel Rubber’s EPDM products stand out for their recyclability, making them an eco-friendly choice for industries in Michigan. Our commitment to environmental responsibility extends beyond manufacturing, ensuring that EPDM rubber contributes to a circular economy, including the use of EPDM sponge gaskets and EPDM sponge seals.

EPDM as a Sustainable Material:

EPDM rubber’s sustainability goes beyond recyclability. Its production process requires less energy compared to many other rubber types, aligning with Michigan’s efforts to promote energy efficiency. Excel Rubber’s EPDM solutions contribute to a more sustainable manufacturing landscape in the state.

EPDM Rubber Advancements and Innovations:

Latest Technological Developments:

Staying ahead in the competitive landscape of rubber solutions requires continuous innovation. Excel Rubber embraces the latest technological developments in EPDM rubber, offering state-of-the-art solutions that meet the evolving needs of industries in Michigan, including advancements in rubber L seal profiles, rubber J seal profiles, and rubber D seal profiles.

Future Prospects and Trends:

Excel Rubber looks towards the future, anticipating the trends that will shape the EPDM rubber landscape. By staying ahead of the curve, we ensure that our clients in Michigan benefit from EPDM solutions that not only meet current needs but also align with future industry requirements.

The future of EPDM rubber holds exciting prospects, including advancements in sustainable formulations, smart materials, and enhanced functionality. As industries in Michigan transition towards eco-friendly practices, Excel Rubber is poised to lead the way with EPDM innovations that contribute to a greener, more sustainable future.

FAQs about EPDM Rubber:

How is EPDM different from other rubber types?

EPDM, or Ethylene Propylene Diene Monomer, distinguishes itself from other rubber types due to its exceptional weather resistance, durability, and versatility. Unlike natural rubber, EPDM maintains its integrity in extreme temperatures, making it an ideal choice for various applications. Excel Rubber’s expertise in EPDM formulations ensures that our clients in Michigan receive rubber solutions tailored to their specific needs.

What are the key advantages of using EPDM rubber?

The key advantages of EPDM rubber lie in its outstanding weather resistance, durability, and versatility. Excel Rubber’s EPDM solutions provide manufacturers in Michigan with materials that can withstand harsh conditions, reducing maintenance costs and ensuring long-lasting performance. EPDM’s adaptability makes it suitable for diverse applications, from roofing systems to automotive seals.

Is EPDM environmentally friendly?

Yes, EPDM is considered environmentally friendly. Excel Rubber prioritizes sustainability in EPDM production, aligning with Michigan’s eco-conscious initiatives. EPDM’s recyclability and lower energy requirements during manufacturing contribute to a reduced environmental impact, making it a green choice for various industries in Michigan.

Can EPDM be recycled?

Absolutely. EPDM rubber is recyclable, supporting Michigan’s efforts towards a circular economy. Excel Rubber encourages the recycling of EPDM materials, reducing waste and promoting eco-friendly practices in the region. Our commitment to recycling aligns with Michigan’s focus on sustainable manufacturing.

How is EPDM used in extreme weather conditions?

EPDM’s exceptional weather resistance makes it a preferred choice for applications in extreme weather conditions. Excel Rubber’s EPDM solutions are designed to perform reliably in Michigan’s diverse climate, offering durability, flexibility, and resistance to temperature fluctuations. Whether in scorching heat or freezing cold, EPDM maintains its structural integrity, ensuring optimal performance.

Conclusion:

In conclusion, Excel Rubber’s FAQ section provides valuable information about EPDM rubber, addressing common queries and highlighting its unique advantages. As a trusted provider of rubber solutions in Michigan, Excel Rubber remains committed to offering insights that help industries make informed decisions about the use of EPDM in diverse applications.

For comprehensive EPDM solutions tailored to Michigan’s industrial needs, trust Excel Rubber to deliver quality, durability, and innovation in every rubber product.