Rubber strips play a key role by supporting a variety of industries which , among many , are bottom line producers for sealing solutions, ancillary protection against spillage , weather elements, noise and pollution. In addition to this fundamental lesson, we will hopefully understand the functioning of different classes for rubber strips, the advantages and disadvantages, and future expanding trends in this tutorial. However, one of the key aspects here is the strip role of rubber plays in improving the working of the tool and maintaining productivity.

Introduction to Rubber Strips

Rubber strips or strips commonly referred to as seals, gaskets or other similar names are the flexible tools which are used to bridging the gaps or the leakage areas between two pieces or surfaces of any structure so as to prevent the escape of air, water, dust or other particles. This quite saving technology is unmatched when talking about leak proof gas protection, thermal insulation, noise reduction, and structural reinforcement all necessary in the automotive, construction, manufacturing, and industrial sectors.

Table of Contents

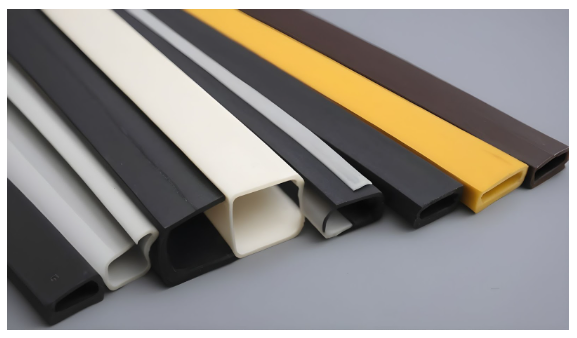

Types of Rubber Strips

Rubber strips are available in different types, each tailored to suit specific sealing requirements:

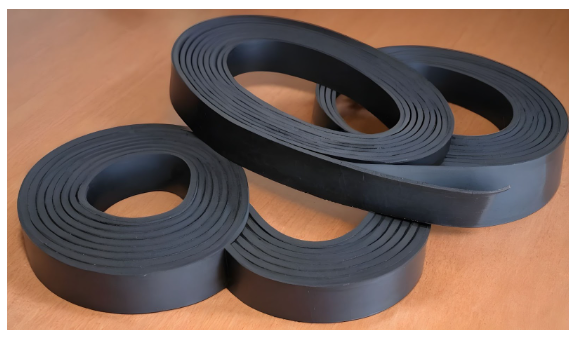

Solid Rubber Strips

Such strips are designed with the function of static sealing that also applies the sealing purpose which ensures a perfectly compressed counterpart that is durable. Likewise, they are highly knowledgeable when it comes to concrete cases where toughness and rigidity is unquestioned.

Sponge Rubber Strips

These belts are of very high tolerance and being ductile they play a vital role in efficient glazing and insulation. They are most widespread in automobiles where they are employed in trim to prevent closing of electrical doors, window rolling, or motion of the car due to shaking or vibration, as well as for cushioning.

Co-Extruded Rubber Strips

They involve various items and materials in a separate band and this in addition to other benefits makes them more efficient in permanently sealing and functioning. They, thus, focus exclusively on the specific issues of the clients; hence, they are better adapted to the most demanding working situations for example, outdoor conditions.

Automotive Applications

Through them being base components of many auto sealing systems other than to the tire manufacturing itself The most commonly used forms such as membranes, foams and tapes are used for door and window sealing, weather sliding and finishes application wherever needed. The primary function of creative issues include silencing noise attenuation, prevention of water infiltrating into the cabin and at the same time fruition of safety and comfort aspects of the drivers as well as passengers.

Construction Sector

Rubber strips have become an everyday feature in the construction industry since there are everywhere possible dozens of applications–for instance, doors, windows, expansion joints, curtain walls and other structural manipulations. Examples are that they do thermal insulation, waterproofing and stopping air infiltration which afterwards brings about energy efficiency, building strength and comfort of normal people.

Industrial Machinery

Rubber (or rubber strippings) is an effective sealer of the compartments, hatches, and enclosures in industrial machinery, contributing to better indoor air quality and preventing any kind of failure on the machine components due to dust, moisture or contaminants, a outcomes of which would be that they would be kept away from the machines from the inside. That is the reason for the longevity of these devices and the best performance signals they give.

Benefits of Rubber Strips

Rubber strips offer numerous benefits that make them indispensable in various applications:

– Flexibility: By their nature of making the rubber strips pre-formed, they can easily be installed on a surface with irregular shape that includes corners that are more complex than the others, therefore, the closing of the place becomes hermetic even in the worst of conditions.

– Durability: These clutch strips will be resilient against the disk level wear and tear and will be able to withstand the storage conditions and natural forces. Consequently, they will be able to function flawlessly.

– Chemical Resistance: Rubber strips are great for flow control applications, whether the substances are oil, chemical, or rough, thus security and performance will work in the most hated conditions.

– Easy Installation: They consume fewer-time and do not need specialties and strenuous efforts to be installed. Due to the fact of the simplicity, they will reduce the maintenance time and the expenditure of those other sealing solutions.

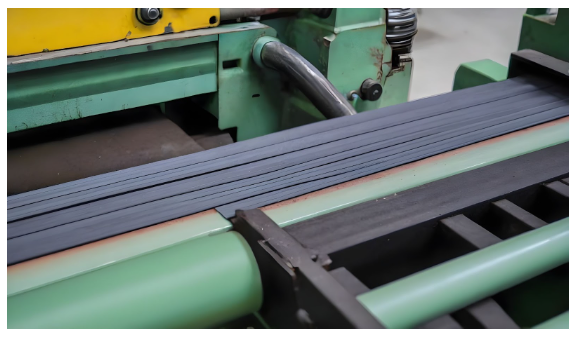

Manufacturing and Customization

Extrusion, cutting and finishing are the primary steps during the production of rubber strips, and these steps can be customized to be smaller, different shape, material type as well as harder, based on clients’ demand. It might be necessary to use different types of rubber materials such as EPDM, neoprene and silicone for the masking strips in order to enable them to work in a variety of environments. District Heating and Cooling not only provide affordable energy but can keep the top level of the service stable as well as allow us to increase the lifetime of the equipment.

Environmental Impact and Sustainability

Eco-friendly design solutions are demonstrated in the main component of the rubber strip, which is that there is a propensity for reuse, and no additional raw materials in the manufacturing processes, ecology, or recycling. Most eco-conscious companies now strive to include regenerative rubber products into their production processes. This idea coincides with the principle of a circular economy and waste reduction which is again one of the most trending topics on the sustainable development pathway.

Challenges and Solutions

The problems, represented in chemical compatibility problems, environmental exposure, and wear resistance issues, are possible challenges which are to be faced by the rubber shoe manufacturing The measures include selection of the most relevant worn out that can meet the specific application requirements, application of perfect elastomer installation technique and followed by a simple periodical practice that will let the strips produce a high performance and efficiency.

Future Trends and Innovations

High performance materials, monitoring, smart sealing systems, IoT for real time-connected systems, and data analysis technology are the modern technical guidelines that manufacturers are using in fabricating rubber strips. This development will be a unique sort of improvement in strip application and consequently its efficiency of course will rise, the level of reliability will increase, as well as the performance will improve involving many industries.

Conclusion: The rubber strips are so versatile and can serve a wide range of applications

Therefore, firstly, we will touch on the list of benefits, which is the first thing while discussing this subject. On the second hand, this way of sealing can depend upon a very specific purpose of sealing that it has and so it acts in a way that is effective following the application of a seal. This is further achieved when we incorporate their contribution with all ongoing technologies and make sure that new versions keep us on the path to getting extra technologies to help us improve the operations of the equipment in various industries. The classification method benefits the raising of the noise suppression performance of the machines and the entire functioning ratings improvement. The explanations in the book are clear and convincing.