Introduction

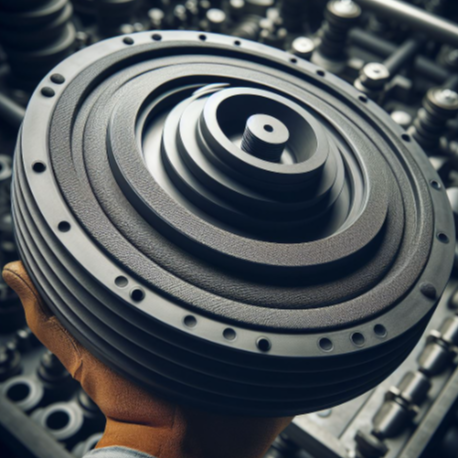

Rubber diaphragms are central elements of manifold mechanical systems in a wide range of industries. Their importance comes from the basic functions they perform such as pressure maintenance, transportation of fluids and isolation of media.

Throughout many fields of industry, ranging from food production to chemical processing, rubber diaphragms denote the true effectiveness of the exigent parameters of a process by improving efficiency and dependability.

In the exploration we will go very deep into the rubber diaphragm analogy, we will open up its significance, there different types, wide range of appliances, particular advantages, the manufacturing process, strict quality standards, and the future it has in store effects the changes that are expected in future.

Table of Contents

Importance of Rubber Diaphragms in Industrial Systems

As to the industrial area, rubber diaphragms take a leading position due to the ability of this product to provide an exact regulation, an extremely long life cycle, and a no-nonsense cost.

These elements are part and parcel of the design, though they may be the hardest to predict in design functional, but resistance to chemical erosion is incorporated in them. Therefore, a rubber membrane goes to be the vital part of the process, that look applies in a wide range of devices such as cars, spacecrafts, medical facilities and machineries.

Types of Rubber Diaphragms

Natural Rubber Diaphragms

Overlapping with the latex inherent, natural rubber diaphragms provide exceeding elasticity and resilience, thus serving well for soft applications or those requiring flexibility. Industries such as construction, mining, and vehicles include the utilization of natural rubber diaphragms due to puncture and tear resistance.

Synthetic Rubber Diaphragms

Due to the development of the new EPDM, Nitrile, and Neoprene fillers synthetic rubber has the characteristics of higher chemical resistance and endurance than natural rubber. In this matter diaphragms can be adapted for use in industries not only under conditions of oil, fuel, and chemical pollution, but also extreme temperatures.

Applications of Rubber Diaphragms

Rubber Diaphragms: Applications in Industrial Systems

Rubber diaphragms being used in huge numbers through a wide range of industrial systems across the globe has brought diaphragms to the forefront. They perform the most crucial role in assuring that everything runs just right, get all the machines operate exactly how they must, or get the whole system perform reliably in extreme situations. Let’s explore some of the key applications of rubber diaphragms in various industries:

Automotive Industry

In the automotive or rubber sector, diaphragms are used extensively in various processes. They have important roles in the fuel systems, especially in the realms of fuel management where they regulate fuel flows within the engine with preset accuracy and effectiveness. Moreover, rubber diaphragms are employed in brake actuators to offer efficient braking and boosting components, which safeguard occupants as well as vehicle performance. In addition to emission control valves diaphragms play a major role in the exhaust gas management and thereby they bring environmental effects to minimum level and ensure meeting of emission standards.

Aerospace Industry

Leading aerospace corporations utilize components consisting of rubber diaphragms in terms of hydraulic and pneumatic control systems. The major function of them is to work as diaphragms of the landing gear, and this operation guarantees smooth and soft process of landing an aircraft On the other hand, they serve as the critical elements in control mechanisms of flights and therefore provide complicated maneuverability and flight stability of the aircraft. Rubber diaphragms are known for their accuracy and reliability which are key considerations for the aerospace industry where the airworthy purpose and performance are quite crucial.

Medical Equipment

Rubber diaphragms have major functions for a wide performance of medical devices and equipment. Diaphragm pumps would be unable to sustain proper fluid flow unless they were composed out of these materials, which are thus essential; they play a crucial role, especially in applications involving drug delivery systems and medical devices that handle fluids. Besides, rubber diaphragms in ventilators supply the means to properly regulate the air pressure and flow. This makes it possible to give lung support to the patients. Moreover, the modern anesthesia machines employ these diaphragms for providing precise delivery of anesthesia gasses and thereby allowing for the retention of medical safety and comfort.

Industrial Machinery

As part of materials used in the fabrication of industrial machinery and machineries, rubber diaphragms feature prominently in industrial process handling. They are usually used in pumps and they achieve the required targets such as fluid control and pressure regulation so that the performance becomes consistent and freedom from failures. The pneumatic valves, regulators, and pressure sensors also use the same rubber diaphragms as the others and this ensures proper operation of these different industrial processes. The utilization of such diaphragms in actuator systems does more than just make the controlled movement and positioning. In fact, it really adds up to the functional capabilities of the system and boosts its productive capacity.

In terms of their myriad of possible alternatives, rubber diaphragms are highly versatile and adaptable to a bunch of tasks. Carbon-fiber, aerospace, medical, industrial equipment and machinery, these parts are the electronics and components being crucial in the operation of such fields.

Benefits of Rubber Diaphragms in Industrial Systems

Rubber diaphragms are equipped with a myriad of advantages that make them the most common and important classic element in the entire industrial world. Let’s explore some of the key benefits provided by rubber diaphragms

Precise Control

One of the principal functions of the rubber diaphragm simply is that they have the capacity to give the needed precision for the handling of pressure, fluid flow and isolating the media. This is a key factor in providing for the industry, helping to attain correct measurements and the regulation operations that are crucial for proper performance and efficiency.

Durability and Reliability

Rubber diaphragms are famous for their resilience and dependability, even though the mentioned circumstances are the toughest and they have harsh working environments. They are able to handle all the different kinds of pressures, temperature variations, and chemical exposure that would otherwise result in production interruptions and periodic shutdowns.

Cost-Effectiveness

Alternative materials are great for reducing costs and construction time; however, the quality of rubber diaphragms is not sacrificed. Their cost-effectiveness is unmatched. This equipment provides the advantages of longevity, durability, and low maintenance making up for the respectable cost differences over its service life.

Versatility and Adaptability

Rubber diaphragms have an irreplaceable facility and can be adapted to applications and industries with different ripeness. Their ability to bend and promote deformation without failing and exposing inner layers to keep functionality constant under various conditions is one of their major advantages of a composite structure.

Chemical Resistance

Polymeric diaphragms show very high resistance against various types of fluids and among them, these include – oils, fuels, acids, solvents, and hydraulic fluids. This product’s properties of chemical resistance means they can be used in environments where there are attacks from corrosive solvents, which guarantees reliability over the years.

Enhanced Safety

However, the sure performance of rubber diaphragms is one of the reasons why many industrial systems are safer than they used to be. The system is designed to manage the fluid movement, overcome pressures, and separate contacting components, resulting in the reduced risk of equipment failure, leaks, and potential injury to personnel among other hazards, and thereby accomplish a safe environment for the workers.

Environmental Compliance

The sensing membranes of the diaphragms help in environmental compliance which facilitates the proper management of the fluids, emissions and waste products within the industrial systems as part of sustainability. Their precision reliability enables industry sectors to conform to the production standards and environmental regulations.

Are you ready to enhance your industrial systems with reliable rubber diaphragms?

In essence, the advantages provided by rubber diaphragms emphasize their irreplaceability within the industrial systems where they continue to contribute towards efficiency, reliability, and optimal output across multiple sectors and applications.

Manufacturing Process of Rubber Diaphragms

Material Selection

The selection of a rubber material that fits the application needs, taking into account the performance parameters like chemical compatibility, temperature resistance, elasticity, and long-term durability may come in handy.

Diaphragm Molding Techniques

Through the use of compression molding, injection molding, or transfer molding methodologies, shaping diaphragms as per engineering requirements of design and dimension, are feasible.

Quality Control Measures

By establishing quality control as a benchmark, together with continually checking dimensional accuracy, material consistency, and performance reliability through tests and inspection procedures.

Importance of Quality and Performance Criteria

Facing a growing challenge of environmental issues and climate change, international organizations have become increasingly aware of the importance of incorporating strict quality and performance standards into their operations and guidelines. On account of this, they have emphasized on environmental sustainability in all sectors of economic, social, and political activities.

Maintaining very powerful performance and reliability criteria will always be an effective instrument for achieving the rubber diaphragms required performance in the industrial applications. Regulation compliance is one of the necessities in the industry, which ensures that our customers trust the company, its personnel, and all its products.

Need expert guidance or have queries about our products?

Common Rubber Testing Methods

Rubber diaphragms undergo various testing methods to ensure quality and performance, including:Rubber diaphragms undergo various testing methods to ensure quality and performance, including:

Physical Testing

Clinicians calculate hardness, tensile strength, elongation, compression set, and resilience factors before making any decision.

Chemical Analysis

Equipment Design: Mechanical components for chemical-composition detection, as well as additive and filler content, and resistance to fluids and chemicals.

Mechanical Testing

Loading evaluation under tension, torsion, fatigue, as well as scratch and wear conditions.

Environmental Testing

Artifi-cial creation of extreme temperature ranges, UV radiation, moisture, as well as the presence of different chemicals.

Non-Conformity Determination Technologies in Rubber Testing

The quality control of rubber may consist of some exhaustive stages, including sampling and preparation of the equipment, calibration, standardized lessons, data analysis, and results interpretation. Through the implementation of these actions the test results are accurate, reliable and this means quality and industry standards are met in the production of the rubber diaphragms.

Future Trends and Innovations

The future of rubber diaphragms in industrial systems is marked by ongoing advancements and innovations, including:The future of rubber diaphragms in industrial systems is marked by ongoing advancements and innovations, including:

Integration with IoT and Smart Systems

With sensors, connectivity, automated monitoring method that is real-time; predictive-prescriptions, and performance optimization.

Advances in Material Science

Designing new rubber compound recipes having superior features like improved hardiness, chemicals tolerations, heat resistance, and the capacity to meet specific demands.

Enhanced Performance Characteristics

Improvements in the design and manufacture of diaphragms, including close tolerances and lighter materials leading to the following performance characteristics: higher pressure rating, lower leakage rate and longer shelf life.

Conclusion

Rubber diaphragms are unquestionable components in industry which offer multifunctionality, reliability, and cost-effectiveness concurrently in numerous other applications. Their characteristics including their capability to withstand harsh environments, control the fluid flow and provide continuous operation, consequently make them an important tool for improving efficiency and reliability in operations across numerous industrial sectors.

Experience excellence with Excel Rubber's molded products

Unique FAQs

Yes, rubber diaphragms can be engineered to withstand high pressures, making them suitable for a wide range of industrial systems.

Factors such as chemical compatibility, temperature resistance, flexibility, durability, and performance specifications based on application requirements.

Yes, manufacturers offer customization options in terms of size, shape, material composition, and performance characteristics to meet specific application needs.

The lifespan of rubber diaphragms varies based on operating conditions, maintenance practices, and material quality but they are known for their durability and longevity.

Regular inspection, cleaning, and replacement as needed are common maintenance practices to ensure optimal performance and longevity of rubber diaphragms.

Rubber diaphragms offer a cost-effective solution due to their longevity, durability, reliability, and reduced downtime and maintenance costs in industrial operations.